Proudly providing specialized solution

- As a manufacturer, We are specialized in the solution of 3D printing, CNC machining, tooling manufacturing, injection molding, metal stamping and die casting process。

- We focus on providing customized production solutions in the field of silicone, plastic, metal stamping and zinc-copper alloy.

- Lingshantech is dedicated to delivering outstanding specialized customer care to our valued customers.

Our Manufacturing Capabilities

Lingshantech: Your Trusted Supplier for Silicone Rubber, Plastic, and Metal Products Lingshantech is a leading and comprehensive supplier specializing in the production of high-quality silicone rubber, plastic, and metal products. With a seamless production chain encompassing R&D, rapid prototyping, CNC machining, tooling design and manufacturing, pilot and mass production, assembly, full inspection, packing, and delivery, we offer a one-stop solution to meet all your manufacturing needs.

3D printing

Lingshantech’s 3D Printing Service enables you to 3D Print your custom part on demand.

CNC machining

At Lingshantech, we have full capacity workshops and machines capable of CNC maching. We offer instant pricing for simple straight lines or geometric shapes.

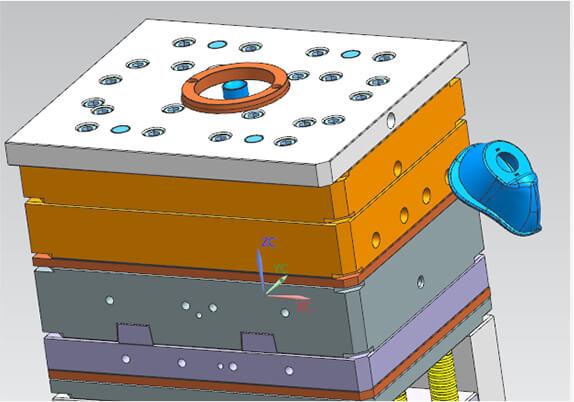

Tooling manufacturing

At LINGSHAN TECH, we manufacture tooling of all types, sizes, and materials. We develop either standardized or completely customized mold concepts depends on specific requirements.

Metal stamping

We specialize in custom metal stamping. Rapid prototyping and large-scale production with high quality and efficiency.

Die casting

Lingshantech boasts advanced die casting equipment and cutting-edge technology. We create die casting mold parts of any shapes based on your drawings.

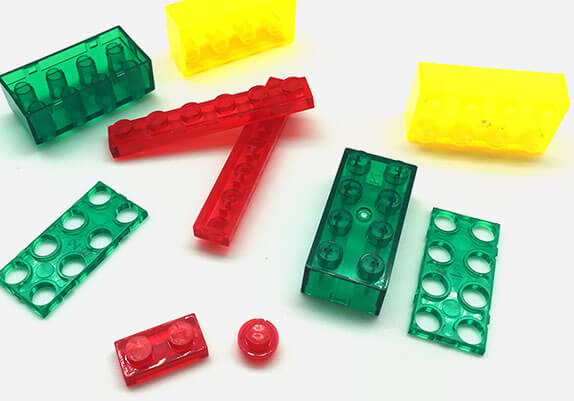

Plastic injection molding

We manufacture plastic parts ranging in size from 3 millimeters to 1 meter, regardless of complexity. Custom high-quality molded plastic parts.

Silicone injection molding

Lingshantech offers full-service LSR manufacturing capabilities. We provide cost-effective solutions for precision Silicone components and assemblies.

Overmolding

Lingshantech stands out as a premier LSR overmolding manufacturer, we offer high-quality custom overmolding services for on-demand production parts.

Silicone rubber compression molding

Lingshantech offers high-quality molds and attention to ensure the delivery of excellent silicone rubber compression components to our customers.

Comprehensive One-stop Solutions for Enhanced Business Efficiency

As a leading provider, we offer customizable and effective solutions of Medical Device, Home&Kitchen, Consumer Electronics, Industrial custom component and Automotive production. Looking to optimize your business operations? Our expertise lies in delivering tailored and efficient solutions that align with your specific goals. We are a trusted manufacturer offering silicone, plastic, and metal parts. Our commitment to excellence and cost-effective solutions makes us the ideal choice for businesses seeking reliable manufacturing partners. Our dedicated team ensures top-notch quality and timely delivery from concept to production.

100+Dedicated Staffs

25Years Serving To Multiple Countries

25Years Serving To Multiple Countries

How Can Lingshantech Help You?

Non-disclosure agreement (NDA)

As part of our commitment to confidentiality, we will sign a Non-Disclosure Agreement (NDA) to ensure the utmost security and privacy for your sensitive information.

Drawing and Requirement

Please submit 2D and 3D files in STEP or X_T format and your product concept and requirements. We excel in material and manufacturing optimization, delivering cost-effective solution

Providing Quotation

Our quote process is designed to provide customers with accurate and cost-effective pricing for customer’s requirements. we offer competitive quotes that align with our customers' budgetary considerations.

DFM and tooling 3D approval

Our experienced team conducts a comprehensive DFM analysis to evaluate the design feasibility and manufacturability of your products. Then we will start to design the tooling 3D for client confirming.

Prototype (3D printing)

We provide rapid prototype manufacturing services using 3D printing technology. This allows customers to quickly obtain physical samples of their customized products.

Tooling manufacturing

Our experienced tooling engineers develop precise solutions that align with your product design and manufacturing needs, using the top-class CNC ,EDM and other precision machines,

Samples and PPAP Approval

After obtaining clients' approval, we supply T0 and P0 samples and comprehensive PPAP documents, demonstrating compliance with industry standards and outlining the production process.

Production and inspection

During pilot and mass production, we leverage expertise, advanced facilities, and quality control measures to efficiently produce high-quality products. Then a final and full inspection ensures the high quality.

Packing and delivery

We consider product size, shape, fragility, branding, and marketing objectives when developing packaging solutions. Additionally, transportation options (sea, air, land) are assessed based on delivery speed, cost, and destination.

why choose Lingshantech

Trusted to deliver the highest level of precision to leading companies in a wide range of industries. Our ISO 9001 certification ensures quality throughout your LINGSHAN experience. Whether it is CNC machining services or one of the many manufacturing processes, LINGSHAN is proud to work with the following industries:

Packing and delivery

We can serve you, we are your reliable contact, in addition to our phoneYou can also give us a message, we will contact you as soon as possible!

Trusted by many industries

Trusted to deliver the highest level of precision to leading companies in a wide range of industries. Our ISO 9001 certification ensures quality throughout your LINGSHAN experience. Whether it is CNC machining services or one of the many manufacturing processes, LINGSHAN is proud to work with the following industries:

Premium Silicone, Plastic and Metal Products for Multiple Industries

We're dedicated to providing top-notch silicone, plastic, and metal products across various sectors. From Medical devices and Home & Kitchen to Consumer electronics, Industrial components, and Automotive applications。

Quality Control & Technical Supports

Raw Material Sourcing

We prioritize the exclusive procurement of materials from trusted suppliers who maintain certified quality management systems at their state-of-the-art facilities. Our suppliers boast a wide range of comprehensive certifications, including rohs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and more. By adhering to this rigorous sourcing approach, we guarantee full compliance with your industry's stringent requirements

Technical Support

At Lingshantech, we take pride in our advanced manufacturing capabilities of silicone, plastic, and metal parts. We specialize in CNC machining, injection molding, and metal stamping, offering highly customized production to meet specific OEM requirements. Our technical expertise ensures seamless collaboration and optimized product development. Trust us to deliver the approved DFM and Tooling 3D with precision and excellence, ensuring top-notch quality .

Quality Control

Lingshantech is a versatile manufacturing company catering to various industries such as Medical Device, Home&Kitchen, Consumer Electronics, Industrial custom component, and Automotive. Our ISO 9001 and IATF 16949 certifications showcase our commitment to excellence, Additionally, our ISO-certified Class 8 cleanroom ensures hygienic manufacturing and minimizes the risk of parts contamination from dust and airborne particles.

Enhanced Machining capabilities with Lingshantech

Our factory is equipped with advanced equipment covering a wide range of manufacturing technologies and processes. We invest in the latest production equipment and tools, including state-of-the-art CNC machines, automated production lines, 3D printers, and ISO Class 8 cleaning rooms for medical manufacturing.

News and Blog

Our factory is equipped with advanced equipment covering a wide range of manufacturing technologies and processes. We invest in the latest production equipment and tools, including state-of-the-art CNC machines, automated production lines,

The ways to implement overmolding with TPE materials

In recent years, with the rapid development of the TPE material industry, the application of TPE materials in overmolding has become increasingly mature. O vermolding can be soft Plastic packaged with hard glue, or soft plastic packaged with hard glue. Depending on the application requirements of the product, the choice of overmolding method is also

Trend of Low-volume injection molding and On-demand manufacturing

L ow-volume injection molding and on-demand manufacturing have emerged as strategic solutions for meeting evolving customer demands and reducing time-to-market. Flexibility in Production: Low-volume injection molding On-demand manufacturing offers the flexibility to produce small batches of parts efficiently . Rapid Prototyping : Both low-volume injection molding and on-demand manufacturing facilitate rapid prototyping. It allows designers

An Overview of Steel Molds

How steel mold work? Steel molds are mainly used in high-volume injection molding manufacturing. It mainly uses different processes. First, the steel is drilled, milled, ground and so on. A nd then the molten plastic is injected into the mold cavity through a high-pressure injection molding machine which will cooled and solidified it under

Ready to get a quote?

Take advantage of our network and see what LINGSHAN can do for you