Tooling Manufacturing Services

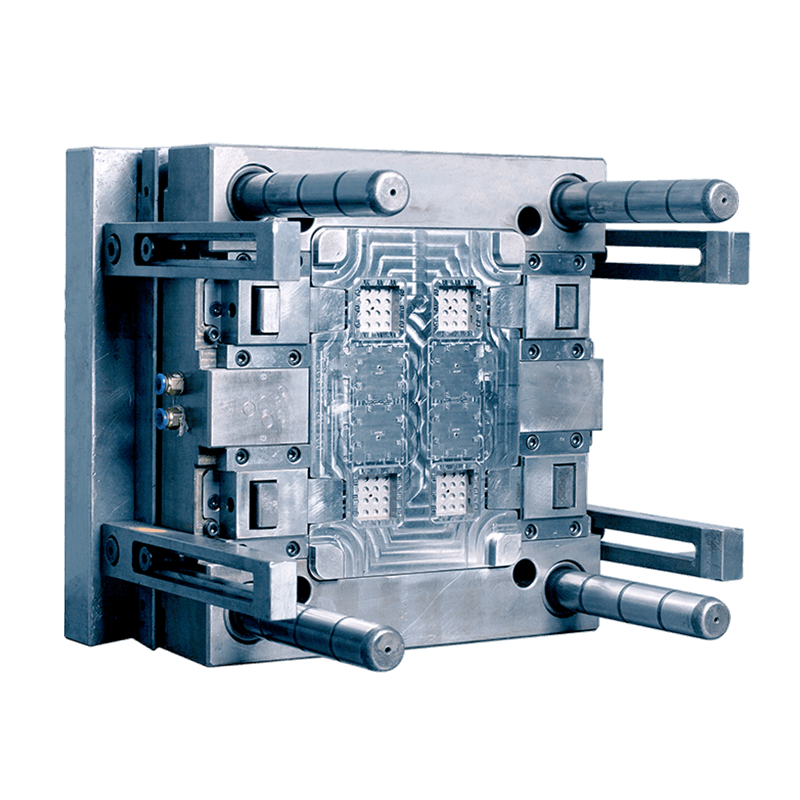

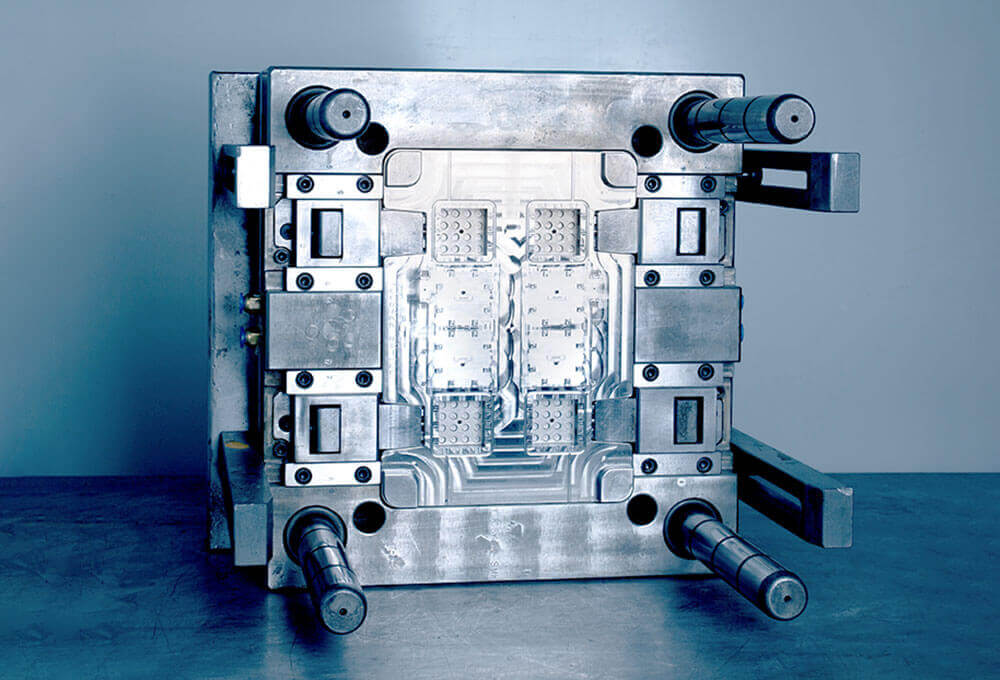

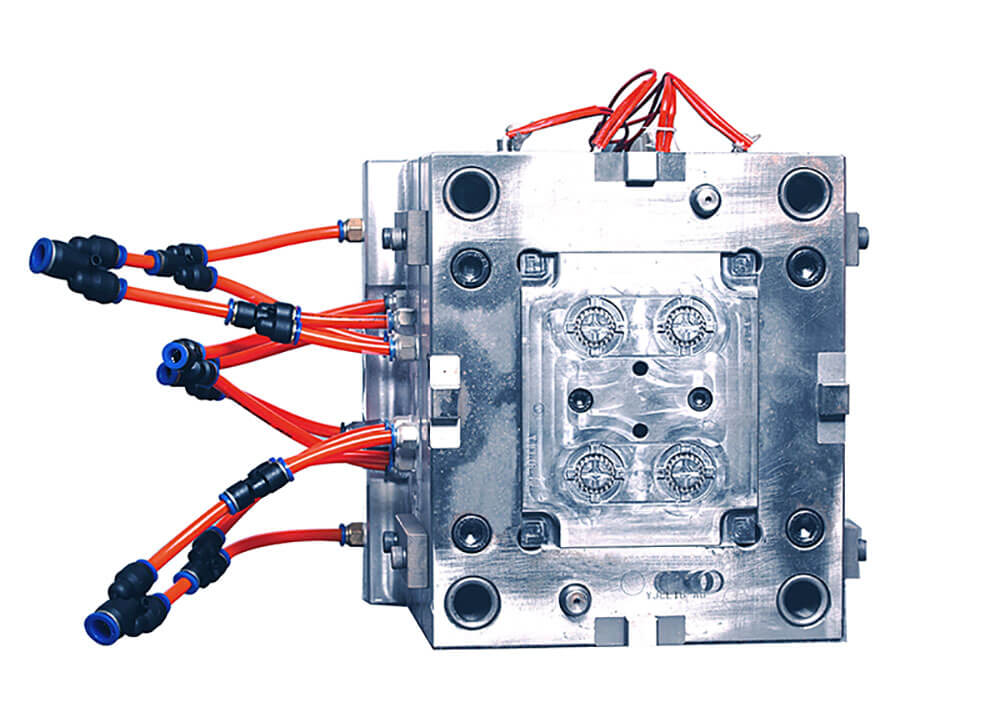

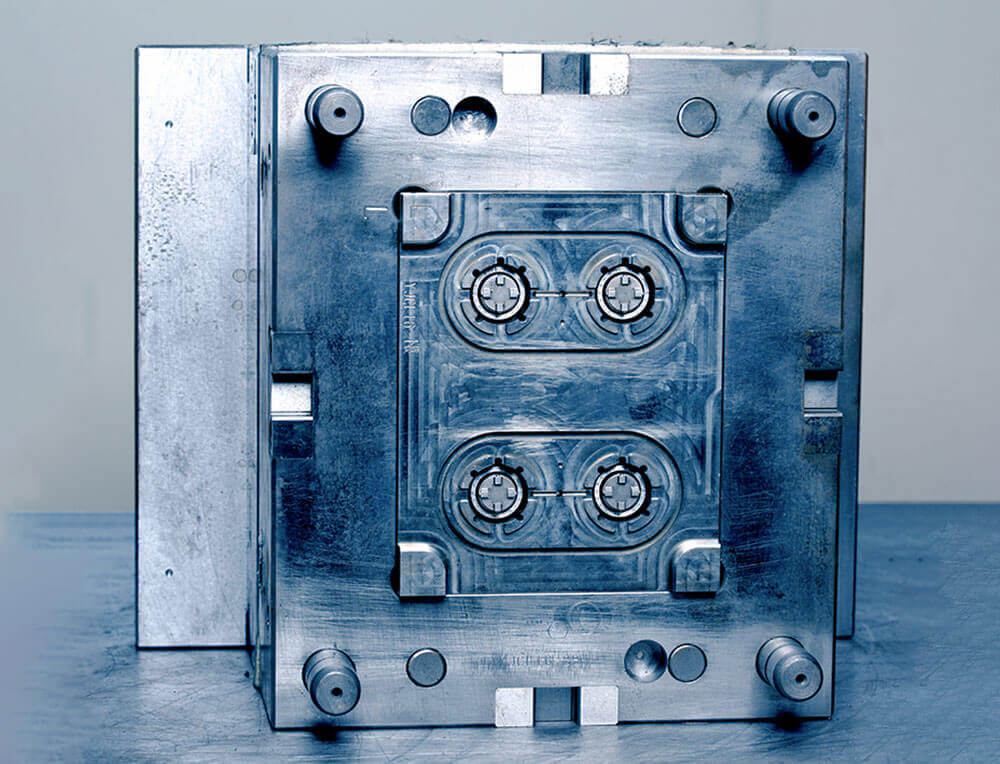

We manufacture tooling of all types, sizes, and materials,we achieve industry-leading precision through investing in state-of-the-art equipment, vibration control, environmental control, and experienced engineers, and machinists.we develop either standardized or completely customized mold concepts depends on specific requirements.

ISO9001:2015

IATF16949

Experience Quality First with Lingshantech

At LINGSHAN TECH, our decades of tooling design expertise extend across various specialized areas, including plastic injection molding, LSR injection molding, plastic and LSR over-molding, silicone compression molding, and silicone and plastic extrusion. We take pride in exceeding the most stringent customer specifications and adhere to ISO 9001 and IATF 16949 quality management standards, ensuring that our results not only meet but surpass customer expectations.

Main Tooling Manufacturing Machines

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |

Why Choose Us?

We offer comprehensive 3D printing solutions with a focus on stringent quality control, advanced equipment, and a wide range of material options to ensure precise, high-quality printing outcomes that meet diverse project requirements.

Advanced Equipment and Technology

We possess advanced manufacturing equipment and technology, including high-precision CNC machines, CAD/CAM software, and 3D printing technology. These advanced toolings enable us to achieve precise manufacturing of tooling and accomplish intricate details and complex shapes with utmost accuracy.

High-quality Materials and Manufacturing Standards

We strictly select high-quality materials for our tooling, such as premium-grade steel and wear-resistant alloys. Additionally, we adhere to strict quality control standards and processes to ensure the manufacturing quality and consistency of each tooling. This contributes to improved durability, stability, and lifespan of the tooling.

Customized Design and Engineering Support

We work closely with our customers, gaining in-depth understanding of their needs and product requirements. Our experienced team of engineers provides professional design advice and engineering support, ensuring that the tooling design meets customer expectations and specific product requirements.

Technological Innovation and Continuous Improvement

As an innovation-driven and continuously improving factory, we constantly pursue technological innovation, exploring new manufacturing methods and materials. By incorporating advanced processes and technologies, we enhance the precision, complexity, and production efficiency of our tooling to meet the ever-evolving market demands.

Our Unique Points

An extensive range of customizable options, seamless collaboration for tailored solutions, and swift manufacturing to capitalize on market opportunities and meet urgent demands

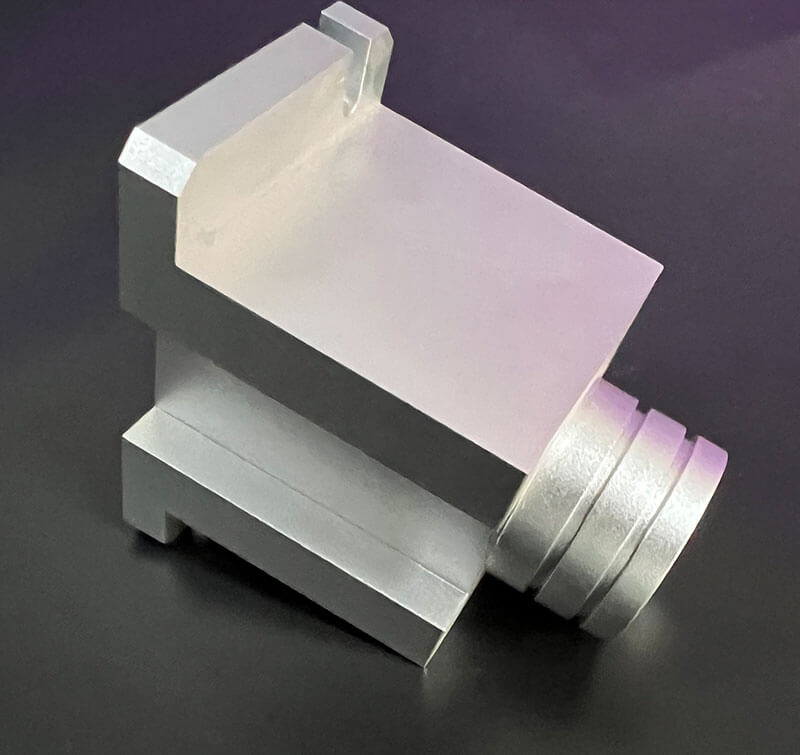

Tight Tolerances

Using wire EDM, 5-axis CNC and other high-precision equipment to achieve tolerances as 0.01mm.

Precision Gages and Fixtures

Through high-precision inspection, maintaining process stability, customization, quality control, design support, cost-effectiveness, and continuous innovation, we are committed to meeting our customers' exacting requirements for molds and delivering excellent long-term return on investment.

High-Level Technology

Our machinists understand what tools they need, including CNC machines, blue prints and quality inspection devices.

Start Tooling Solutions Tailored to Your Specific Needs

Send us an inquiry today to unlock precision, efficiency, and exceptional performance for your tooling manufacturing processes.

Materials

P20 (P20HH)

S136 (S136H)

NAK80

H13

718 (718H)

2738 (P20+Ni)

2316

MoldMAX

Aluminum

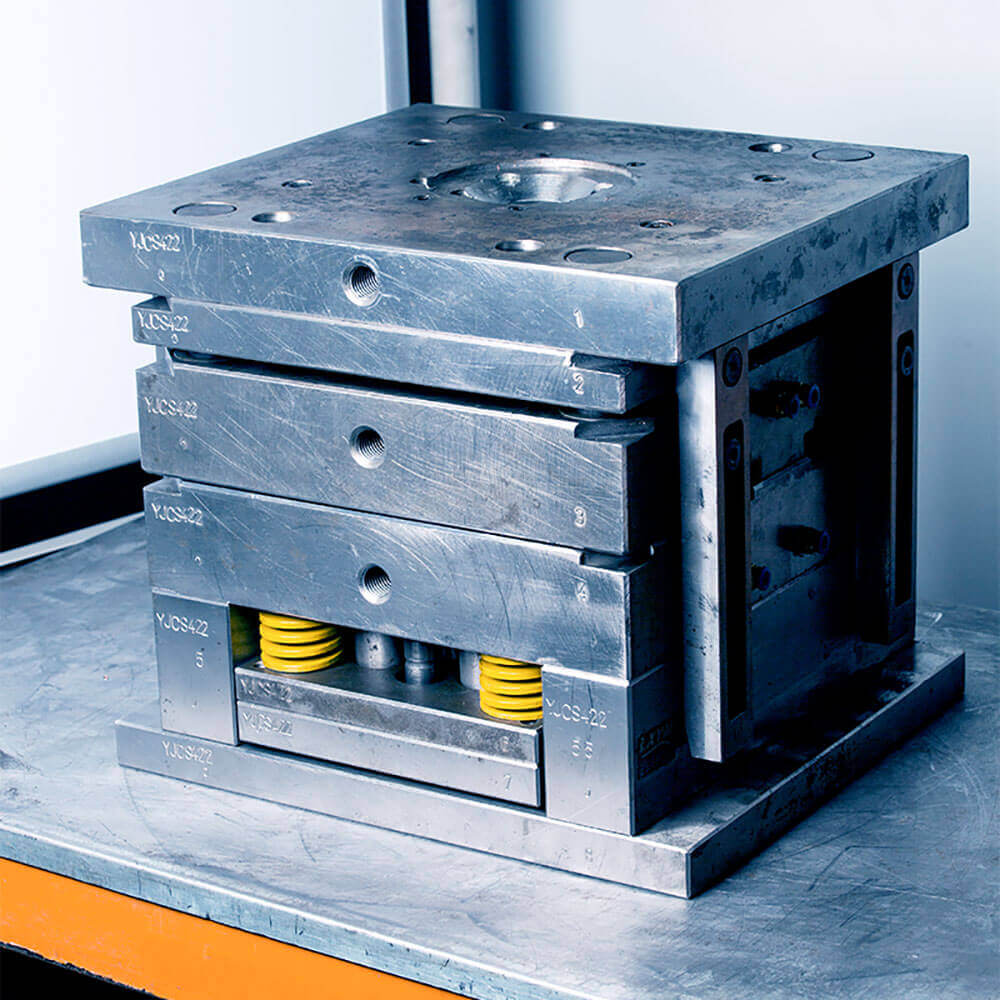

Types of Tooling

Prototype Tooling

Prototype tooling, also called soft tooling or rapid tooling, allows manufacturers to design, produce, and test tools to assess fit, form, and function before full-scale production. Materials like silicone rubber, aluminum alloy, and soft steel are commonly used for their cost-effectiveness and ease of shaping. The benefits include rapid production of prototypes in hours or days, lower investment costs, and the ability to produce accurate parts for testing and validation.

Complementary Services

- Design and Engineering

- 3D Printing

- Large-Scale 3D Metal Printing

- CNC Machiningy

- Fabrication and Welding

- Assembly and Finishing

- Inspection and Testing

The Application of the Molds Produced by Lingshantech

The molds produced by Lingshan Technology has diverse application fields, showcasing their versatility and precision. Some of the key areas where these molds find extensive use include:

Common 3D Printing Applications

- Automotive Industry: internal components, external body panels, and engine parts.

- Consumer Electronics: smartphone casings, laptop casings, and other electronic components.

- Medical Devices: medical equipment, devices, and packaging.

- Packaging: customized packaging solutions, including containers, bottles, and caps.

- Aerospace: aerospace components and structural parts with exceptional precision and reliability.

- Appliances: refrigerator parts and washing machine components.

- Toys and Games: various toy components and game pieces.

Industrial Equipment:parts and components for industrial machinery and equipment. - Customized Manufacturing: customized mold solutions to meet specific customer requirements.

- Prototyping and Production: for fast prototyping and efficient production.