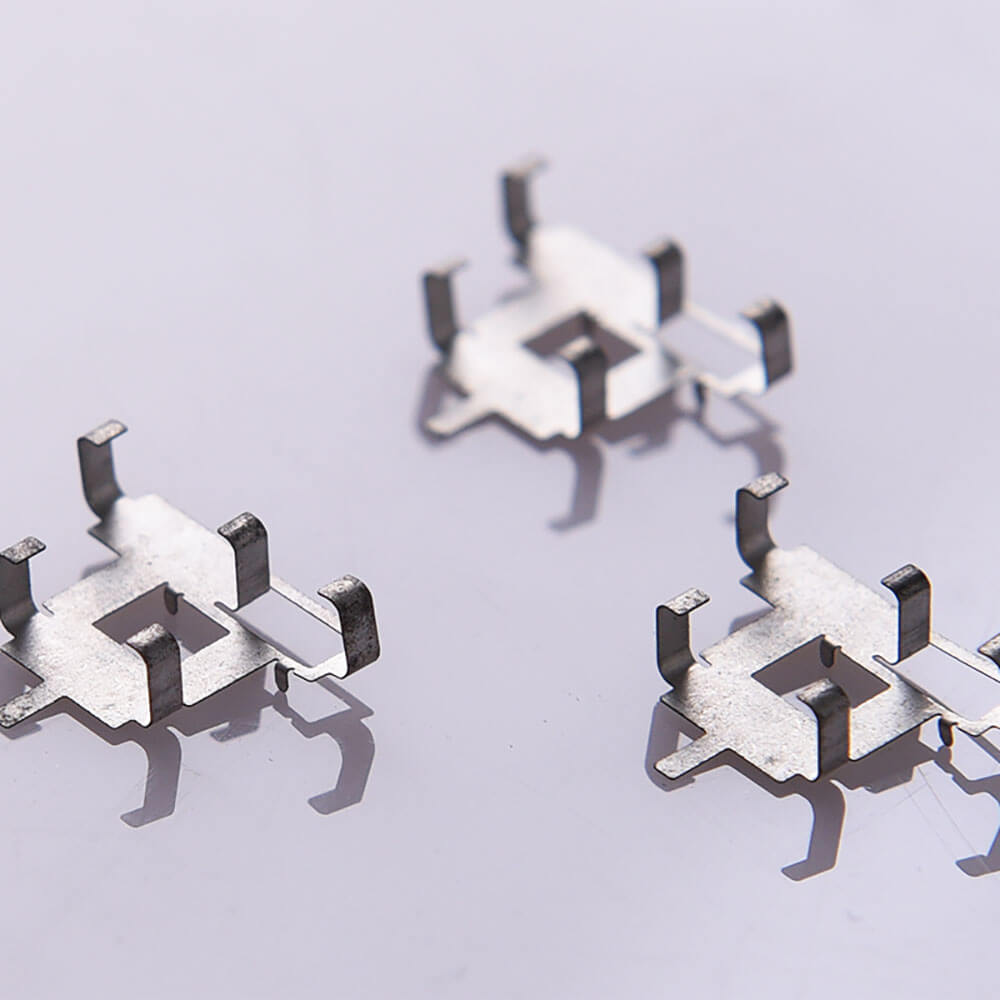

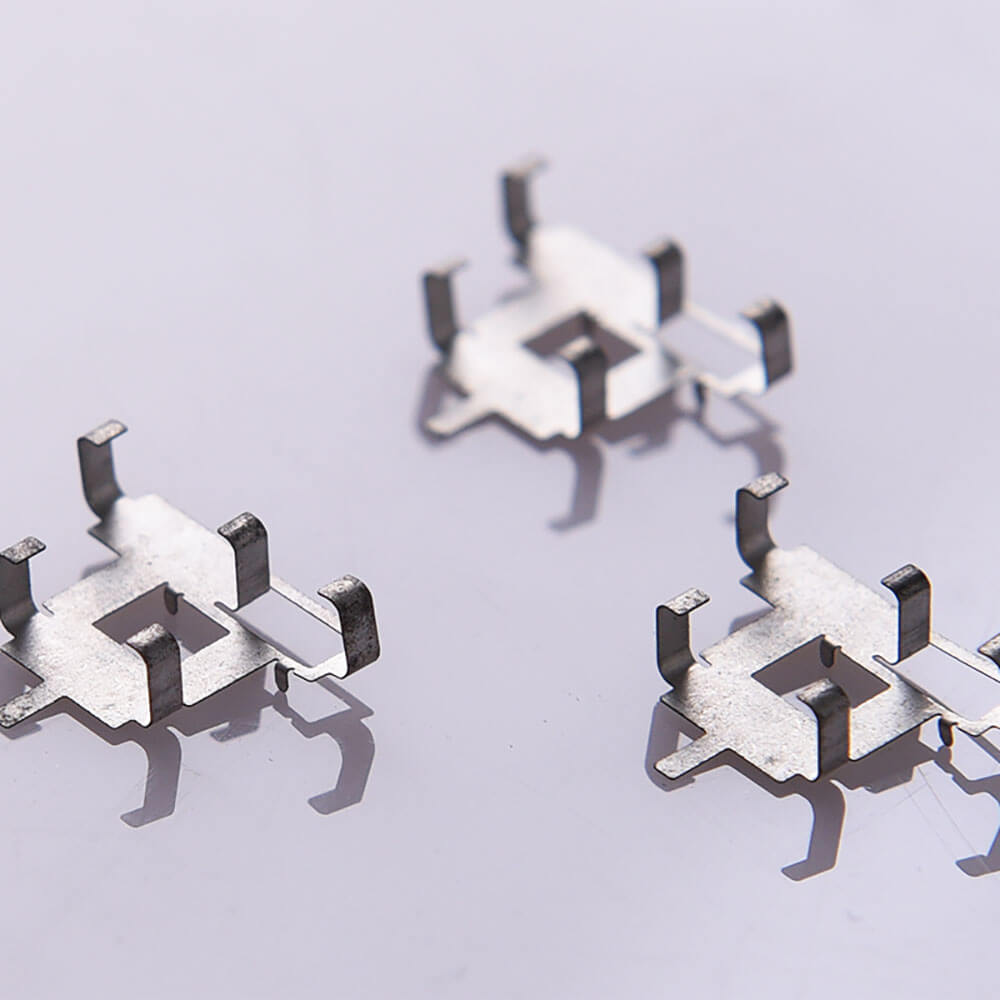

Precision Metal Stamping for Custom Component Parts

We provide comprehensive metal stamping services, covering everything from initial design to final delivery, including material selection, process optimization, rapid prototyping, and large-scale production, to meet your customized needs with high quality and efficiency.

Custom Precision Metal Stamping for Global Industries

We specialize in custom metal stamping using materials like copper, brass, stainless steel, and steel alloys. This advanced technique enables us to fabricate a wide array of metal stamped components, varying in shape, size, and complexity, while reducing lead times and production costs. Our expertise serves diverse industries worldwide, delivering premium metal stamped parts.

Why Choose Us for Metal Stamping Service?

Advanced Equipment and Technology

We have invested in state-of-the-art metal stamping equipment and technology, including high-speed presses, multi-station dies, and automated production lines. The utilization of these equipment and technologies allows us to produce metal stampings at higher speeds and with greater efficiency.

Multi-Station Stamping Technology

We employ multi-station stamping technology, which enables multiple operations such as cutting, bending, forming, and piercing to be performed simultaneously on a single press. This technology not only improves production efficiency but also reduces the handling and movement of components, resulting in lower production costs.

Quality Assurance and Certification

We are committed to delivering high-quality metal stampings and hold ISO 9001 and IATF 16949 certification for our quality management system. We implement strict quality control measures throughout the production process, including material inspection, process control, finished product testing, and validation, to ensure that each product meets customer requirements and standards.

Material Selection and Optimization

We collaborate with suppliers to select high-quality metal materials and optimize them based on customer requirements. Through proper material selection and optimization, we enhance the strength, corrosion resistance, and wear resistance of the products to meet various application needs.

High Precision and Consistency

We strictly control the process parameters and quality requirements of each production step to ensure the precision and consistency of every metal stamping. We utilize advanced measurement equipment and quality control tools for inspection and validation to ensure that each product meets the specified requirements.

Engineering Support and Collaboration

We have a professional engineering team that works closely with customers, providing technical support and solutions. We offer expertise in product design, process optimization, and cost control, assisting customers in achieving the best metal stamping solutions.

Our Unique Points

An extensive range of customizable options, seamless collaboration for tailored solutions, and swift manufacturing to capitalize on market opportunities and meet urgent demands

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Seamless Customization

We collaborate closely with you to bring your vision to life. With a wide array of materials, colors, and finishes, your creative ideas take shape with precision and unmatched quality.

Shorter Delivery Times

We can start manufacturing immediately according to your needs, achieving rapid delivery, enabling you to seize the market opportunities and meet urgent customer demands.

Start Making Custom Metal Stamping Service

Unlock limitless possibilities in metal stamping with our expertise and precision—send us your inquiry today!

Available Materials for Metal Stamping

| Material | Grades Available | Key Properties | Common Applications |

| Steel | CRS (Cold Rolled Steel) | Excellent formability and versatility | Cold forming applications |

| 1008 | |||

| 1010 | |||

| 1018 | |||

| Stainless Steel | 301 | Exceptional tensile strength | Structural components, springs |

| 304 | Enhanced performance and corrosion resistance at higher temperatures | Food processing equipment, plumbing | |

| 316/316L | Best corrosion resistance (higher cost) | Marine environments, medical devices | |

| Copper | C110 | Excellent electrical conductivity, easy formability | Electrical wiring, conductors |

| Brass | Brass 230 (85/15) | Highly formable, corrosion-resistant | Plumbing fittings, electrical connectors |

| Brass 260 (70/30) | Musical instruments, decorative items |

Tolerance of Metal Stamping Parts

| Size Range (millimeters) | Tolerance Range (millimeters) |

| 0 - 10 | ±0.05 |

| 10 - 20 | ± 0.1 |

| 20 - 50 | ± 0.2 |

| 50 - 100 | ± 0.5 |

| 100 - 200 | ± 1 |

| 200 - 500 | ± 2 |

| 500 - 1000 | ± 5 |

Surface Finish Options for Metal Stamping Parts

- Electroplating

- Powder Coating

- Anodizing

- Painting

- Passivation

- Brushed or Polished Finishes

- Galvanization

- Blasting

- Chemical Etching

- Laser Etching

What Is Metal Stamping?

Metal stamping is a manufacturing process used to shape and form metal sheets or coils into the desired parts, components, or products. This process typically involves placing flat metal material onto a press and then using the pressure and motion of dies to alter the material's shape, ultimately producing the required parts.

Here Are the Fundamental Steps of the Metal Stamping Process:

The Advantages of Metal Stamping as A Manufacturing Process Include:

- High Efficiency

- Precision

- Cost-Effective

- Versatility with Materials

- Complex Geometries

- High Repeatability

- Rapid Production

- Low Waste Generation

- Suitable for Large and Small Parts

- Wide Range of Industries

Applications of Metal Stamping Dies

Additive manufacturing can be leveraged for both rapid prototyping and production in aerospace, medical, automotive, and other large industry sectors. Examples of typical parts, include:

Common 3D Printing Applications

- Aerospace:precision parts for aircraft and spacecraft, including structural components and connectors.

- Appliances:parts for household appliances such as washing machines, ovens, and refrigerators.

- Medical Devices:produce intricate and small components for medical devices, including surgical instruments and equipment.

- Consumer Goods:Various consumer goods, including furniture, lighting fixtures, and hardware, require metal stamping dies for producing metal components.

- Construction:building components like brackets, fasteners, and structural parts.

- Telecommunications:components for telecommunications equipment, including connectors and enclosures.

- Renewable Energy:renewable energy equipment, such as solar panel mounts and wind turbine components.

- Military and Defense:components like weapon parts, armor, and communication equipment.

- Jewelry and Accessories:Metal stamping dies are used in the jewelry industry to create intricate designs and patterns on metal pieces for ornaments and accessories.

- Custom Manufacturing:for specific, unique projects in various industries where precision metal components are required.