LSR Hearing Aids Components

Lingshantech is a perfect provider for hearing aids parts by using the over-molding process for our customers.Our advanced production capabilities, outstanding quality and two decades of experience with liquid silicone rubber (LSR) components make us an ideal partner for your project.

Overview

Working with Lingshantech, an experienced expert in LSR/Silicone/Plastic and manufacturing technologies, ensures you’ll not only get exceptional care and reliability, you’ll also get the best solution to meet your specific production needs.

Sufficient Facilities

For some medical products, hygiene is critical and requires production in a hygienic, environmentally controlled environment.To meet these needs, Lingshantech offers LSR Multi-Shot molding and over-molding in our own ISO-certified Class 8 Cleaning Room.

Customization Available

We can produce hearing aid parts in various hardness,sizes,colors and shapes according to your specific requirements.

Product Range

Our products can be used in many types of hearing aids, the most typical applications are in ear-back hearing aid, in-ear hearing aid, ear canal hearing aid and full ear canal hearing aid.

Competitive Price

Lingshan tech is a professional manufacturer of in-house and high effective, we provide you with competitive prices and guaranteed service.

● ISO Class 8 Clean Room

● Quality Control

● Low & High Volume Manufacturing

● Competitive Price

● Reliability&Stability

Lingshantech's high level of molding expertise, cutting-edge machinery and continuous strict quality control allow us to ensure consistent and efficient production with high quality output.

Why Is LSR a Good Material for Hearing Aids Components?

Biocompatibility & Hypoallergenic

Any item that requires close contact with the body for an extended period of time, such as hearing products, needs to be biocompatible and hypoallergenic. LSR is a common material used to make these types of products because it has these properties.

Comfortable

LSR has a soft, smooth texture that makes it pleasant to the touch. Due to its softness and flexibility, it will conform to the shape of the ear, providing a comfortable experience for the user. It will not cause skin reactions or irritation and is comfortable enough even for prolonged use.

Chemical Stability

Products for use in the ear should be clean and safe. An important factor in LSR's good biocompatibility is its chemical stability. Silicone rubber is a chemically inert product, so it is not adversely affected by sweat and other environmental or cleaning substances during use.

Design Flexibility

LSR is very versatile and can render complex shapes, including those with complex designs, thin walls, undercuts, and is also suitable for small parts.

Antimicrobial Properties

LSR materials possess antimicrobial properties, reducing the risk of bacterial growth and helping maintain the hygiene of the hearing aids.

High Precision

LSR material can be used for precise mold injection molding, ensuring the creation of very accurate hearing aid casings to ensure a perfect fit with internal electronic components.

The LSR Hearing Aids Accessories We Offer Include but Are Not Limited to the Following Types

About Our Factory

As a one-stop OEM service solutions provider, we employ cutting-edge LSR injection molding technology to ensure each hearing aid casing possesses a seamless and airtight seal. Our commitment to customization allows users to select from a variety of colors and exterior designs, catering to their unique preferences. We offer comprehensive services that encompass product design, sterilization, assembly, and more.

Capability

Our expertise extends to the micro-molding and precision manufacturing of critical medical components. Leveraging advanced micro-molding technology and precision manufacturing techniques, we ensure the highest level of accuracy and quality in our products. To meet the stringent hygiene requirements of our customers, we maintain a Class 8 Clean Room environment. With over two decades of experience in product development and specialized manufacturing technologies, including over-molding, injection molding, multi-shot molding, and more, we are committed to delivering unique and reliable solutions for precision medical components.

Custom LSR Overmolding Solutions

Lingshantech is an expert who understands nuances of working with LSR and thermoplastics as well as the appropriate tooling and processes for each.Every aspect of the LSR overmolding/insert plastic molding process can be customized to produce liquid silicone parts as your specifications. We can assist with economical mold design and development, prototyping, and more.With design flexibility, advanced technology and exceptional quality,Lingshantech is a excellent partner to manufacture your Liquid Silicone components.

Overmolding Technology Provides Technical Advantages for LSR Hearing Aids Components,Including:

Enhanced Sealing

Overmolding technology creates a tightly bonded outer layer, effectively reinforcing the sealing of hearing aid components. This reduces the risk of moisture, dust, and impurities ingress, safeguarding the internal electronic components.

Complex Geometries

Overmolding allows for the effortless realization of complex geometries, which is advantageous for specialized design requirements within LSR hearing aid components. It can provide a personalized appearance and functionality to different parts.

Optimized Structures

Overmolding can create structural enhancements between different components, improving overall strength and stability while reducing material waste.

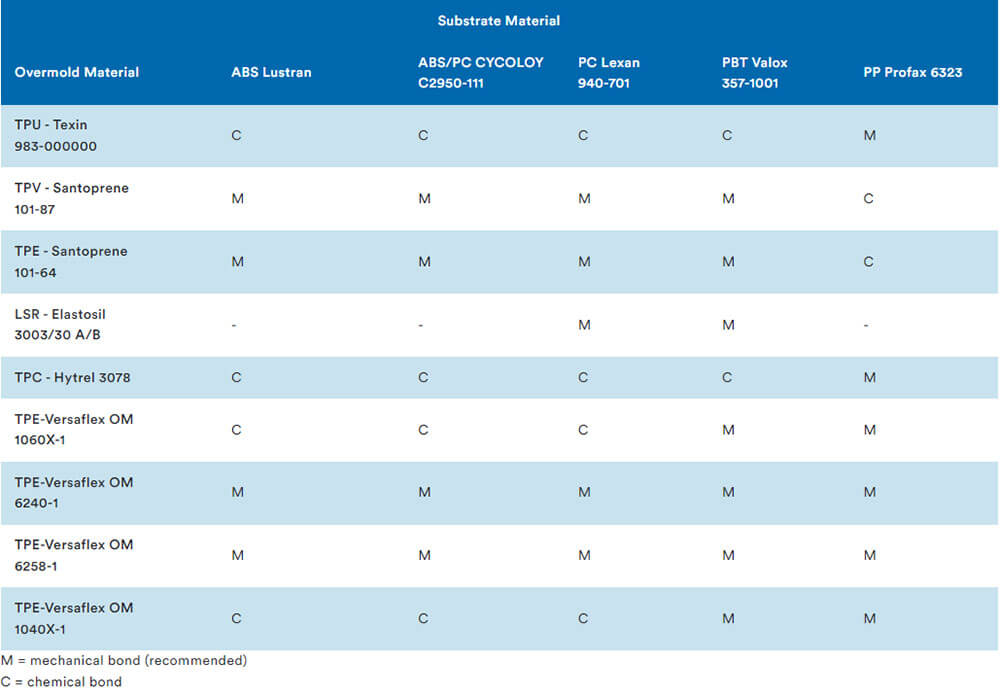

Material Compatibility

LSR material can bond with many other materials during the overmolding process, allowing manufacturers to choose material combinations suitable for specific applications, thereby enhancing performance.

Precision and Repetition

Overmolding processes are highly precise and repeatable, contributing to ensuring consistent high-quality results for each LSR hearing aid component.

Cost Reduction

By consolidating multiple steps into one, overmolding technology can reduce manufacturing costs, decreasing labor and material waste.

Parameter