Overview

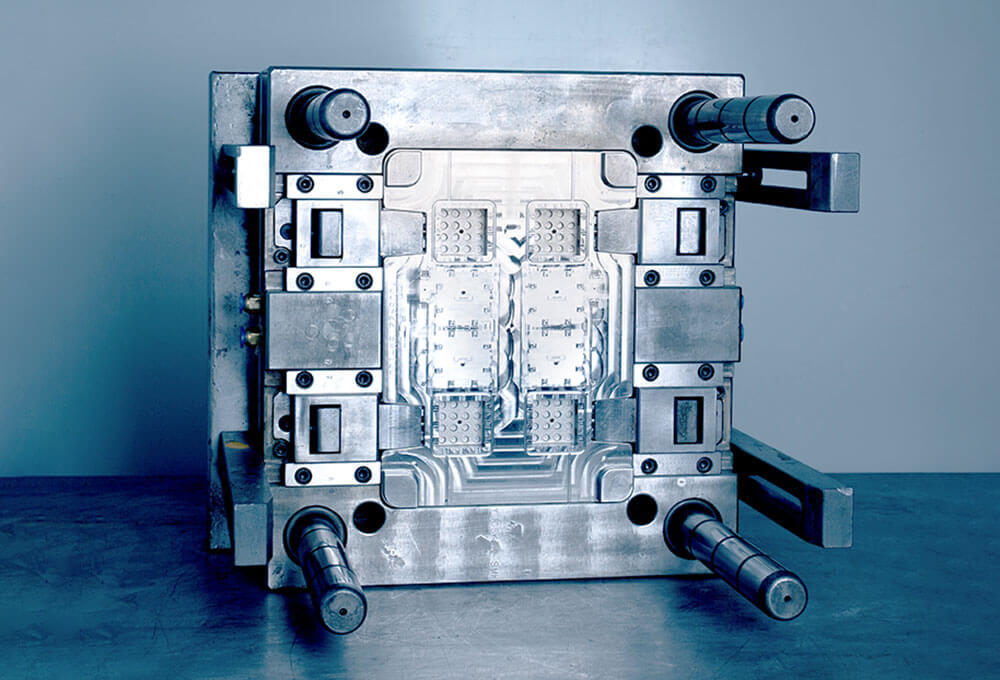

Our core services include mold design and making for injection molding, die casting, compression molding,over molding,2-shot or multi-shot molding and the surface finishing and subsystem assembly for a variety of industries and product lines, ranging from industrial supplies, automotive industry, medical devices, household products, mother and baby products, etc.

Professional

We have more than 20 years experience in this field with our own R&D team, which assure that we can design and produce most kinds of molds as your requirements to meet your needs.

Advanced Equipment

We have the high quality CNC and EDM machines from HAAS, MOKRON, OKUMA, AGIE, MAKINO, such as: 4-axis and 5-axis CNC machines, can offer stable and accurate processing ability.

Quality Guarantee

We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system.

End to End Service

We are the factory to make mold and molded parts, provide customer one-stop service from mould design --3D drawing confirmed--tooling making--MP--Second processing--appearance treatment--packaging--Outgoing.,which help our customer to save time & money

● Rapid Prototyping

● Tolerances Down to+0.03mm

● DFM Feedback

● Precision Machining

One-stop Solution

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping. Our dedicated team of skilled engineers offers a full injection mould tool design service with considerable experience including single cavity, multi-cavity, hot runner, over-mould, and 2k tooling.

Our LIM Tooling Making Capabilities

Multi-out Progressive Dies

Secondary Tools

Machine Automation

Short Run Tools

Precision Gages and Fixtures

Integrated Vision Systems

LSR Injection Products

LSR injection molds are versatile and suitable for a wide range of products, including but not limited to household, medical and electronic components, baby products, washers, bathroom accessories, medical masks and various assembly parts.

Factory Show

Injection Molding Shop

Lingshantech has 60 ton - 160 ton LSR injection molding machines 10 sets,3000 square feet injection molding room including 250 square feet M8 class clean room.We can produce parts from 0.01pound to 13 pounds.

Precision LSR Manufacturing Capabilities

Lingshantech choose the first-class LSR injection machining equipment in the world, cooperated with many-sided tooling manufactory technology, can achieve micron-level in tool manufacturing, and it perfectly achieved required precision for LSR tool. By using AR BURG、2KM etc. manufacturing equipment, Lingshantech can make ultra-precision LSR products with weight minimum to 0.01g,thickness minimum to 0.05mm.

Mold Making Shop

Lingshantech has In-house tooling - fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Equipments

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |