LSR Overmolding Shower Head Nozzels

Lingshantech is a solutions provider for businesses with in-depth experience and advanced capabilities in the development, production, injection molding and assembly of silicone shower head components.

Overview

We have in-house silicone rubber shower head production technology, including mold design, component manufacturing, and assembly, providing you with a one-stop custom solution.

Multi-material manufacturing

We can work with various materials, such as plastics, metals, and silicone rubber, to meet the requirements of different shower head components.

Process versatility

Employing different processes like injection molding, LSR overmolding, and metal processing allows us to address the specific manufacturing needs of various components.

Precision machining

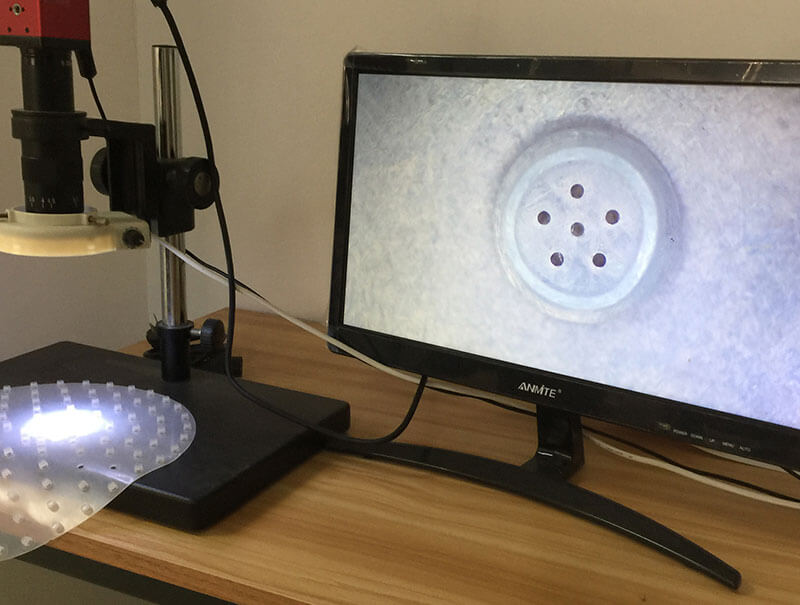

Through high-precision mechanical machining and advanced manufacturing equipment, we ensure the high-level accuracy of shower head components, guaranteeing their performance and quality.

Customization

We can customize shower head components according to specific customer requirements, including size, shape, color, and material selection, catering to the diverse demands of various markets and brands.

● Rapid Prototyping

● Precision Machining

● Free of Hurr

● DFM Feedback

One-stop Solution

As a professional silicone rubber product manufacturing factory, we possess proprietary mold manufacturing technology, which includes mold design, fabrication, and assembly. This ensures that our shower head components are burr-free and manufactured according to customer design specifications.

-

Why is

Some Common Features &Advantages of LSR Silicone Shower Head Nozzles:

Excellent Sealing

LSR Silicone Shower Head Nozzles are manufactured using a one-piece injection molding process, ensuring outstanding sealing performance, preventing water leakage or backflow.

High-Temperature Resistance

Liquid silicone exhibits excellent heat resistance and can withstand prolonged exposure to high temperatures, making it durable even with hot water.

Anti-Yellowing and Aging

LSR material is resistant to yellowing and aging, maintaining an attractive appearance even after prolonged use.

Chemical Resistance

LSR Silicone Shower Head Nozzles are highly stable against chemicals and are not easily affected by chemical substances in water.

Durability

LSR Silicone Shower Head Nozzles have high strength and resilience, capable of withstanding daily impacts and pressures, resulting in a longer lifespan.

Soft &Comfortable

LSR material is soft and skin-friendly, enhancing the comfort of the showering experience.

LSR Overmolding Showe Head Nozzle

Silicone Shower Head ozzle, which known as spray nozzle, water & air nozzles, as elastomeric omponnets at the end of an enclosed tubing, pipe & pump, or bottle to control the spray, direction andcharacteristic of fluid flow and used in water or air spray control products like silicone shower headnozzle, faucet nozzle, hose nozzles, bottles nozzle valve,jet spraying etc.

-

Our Manufacturing Capabilities

Professional LSR Injection Technology

High-Precision Mold Manufacturing

Stringent Quality Control

Customization Capabilities

Mold Design&Manufatruring

FDM Surpport

Factory Show

Precision Manufacturing Expertise

Through high-precision mechanical machining and advanced manufacturing equipment, we achieve highly precise machining of shower head components to ensure their performance and quality. We pay close attention to details such as eliminating burrs, precise assembly, and smooth surface finishing, ensuring that each component meets exceptional craftsmanship standards, ultimately delivering defect-free, high-performance products to users.

LSR Product Manufacturing Capability

Lingshantech cooperates with many-sided tooling manufactory technology, can achieve micron-level in tool manufacturing, and it perfectly achieved required precision for LSR tool. By using AR BURG、2KM etc. manufacturing equipment, we can make ultra-precision LSR products with weight minimum to 0.01g,thickness minimum to 0.05mm.

Mold Making Shop

Lingshantech has In-house tooling - fully equipped 6000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.

Equipments

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |