Plastic Injection Tooling

Lingshantech has complete production chain from R&D, rapid prototypes, mould design, mould making, components production, assembling, packing to export.

Overview

Lingshantech is an experienced mold-making service provider offering many services beyond competitors:

Instant Quote & DFM Analysis

Our engineers will check the feasibility of your design, including part geometry when providing a quotation. Still, we can provide fast and comprehensive DFM feedback reports and competitive pricing before production begins. In the DFM report, we will identify any errors or issues that may cause manufacturing issues on the line.

Wide Range of Molds

Lingshantech has advanced mold-making equipment and excellent partners, which can provide many different types of molds. You can avoid splitting processing projects; you send us everything, and we can solve all your problems in one-stop Problems, to ensure the progress and quality of the proje

Consistent High Quality

We strictly implements the ISO9001&ISO13485 quality management system to ensure that the product quality is consistent and meets expectations. A thorough inspection also ensures that you receive molds free of unwanted defects.

Engineering Support

No matter where you are in the world, our engineering support is available, year-round. Our experienced engineers can provide the most suitable solution for your part design, material selection, surface treatment options, and delivery time.

● Rapid Prototyping

● Tolerances Down to ±0.0004″ (0.01mm)

● DFM Feedback

● Precision Machining

One-stop Solution

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping. Our dedicated team of skilled engineers offers a full injection mould tool design service with considerable experience including single cavity, multi-cavity, hot runner, over-mould, and 2k tooling.

Considerations

The Plastic Injection Mold Tooling Manufacturing Involves Multiple Critical Steps &Considerations:

Design and Engineering

This process begins with precise design and engineering. Experienced engineers carefully plan the mold's geometry, dimensions, and cooling channels to ensure it meets the required specifications for LSR injection molding.

Material Selection

Choosing the right material for the mold is crucial. Typically, molds are made from high-quality steel or special alloys to withstand the extreme temperatures and chemical properties encountered during LSR injection molding.

Machining and Fabrication

The selected materials undergo advanced machining techniques, such as CNC machining, electrical discharge machining (EDM), and wire cutting. These processes ensure the mold's precise geometry and surface quality.

Cooling System Integration

The mold integrates internal cooling channels or systems to manage and regulate temperature during the LSR injection process. Proper cooling is crucial to maintain product quality and reduce cycle times.

Multi-Cavity Molds

In situations where efficiency is paramount, multi-cavity molds may be utilized. These molds enable simultaneous production of multiple identical or different LSR parts in a single molding cycle.

Dimensional Precision

Achieving precise dimensional control is essential to ensure the LSR injection mold consistently produces parts that conform to specifications and exhibit uniform quality.

Lingshantech Has Comprehensive Electronic Enclosure Custom Solution to Fit Your Needs for Every Application

Plastic Injection Molding Products

Plastic injection manufacturing allows for the creation of products with complex and intricate shapes, including thin-walled structures, internal features, and details. These products can serve a variety of functions, ranging from structural components to decorative elements. Plastic injection molding is a cost-effective method for large-scale production and finds widespread applications across various industries, including automotive, electronics, medical devices, consumer goods, and packaging

Our LIM Tooling Making Capabilities

Multi-out Progressive Dies

Secondary Tools

Short Run Tools

Customization Capabilities

Precision Gages and Fixtures

Integrated Vision Systems

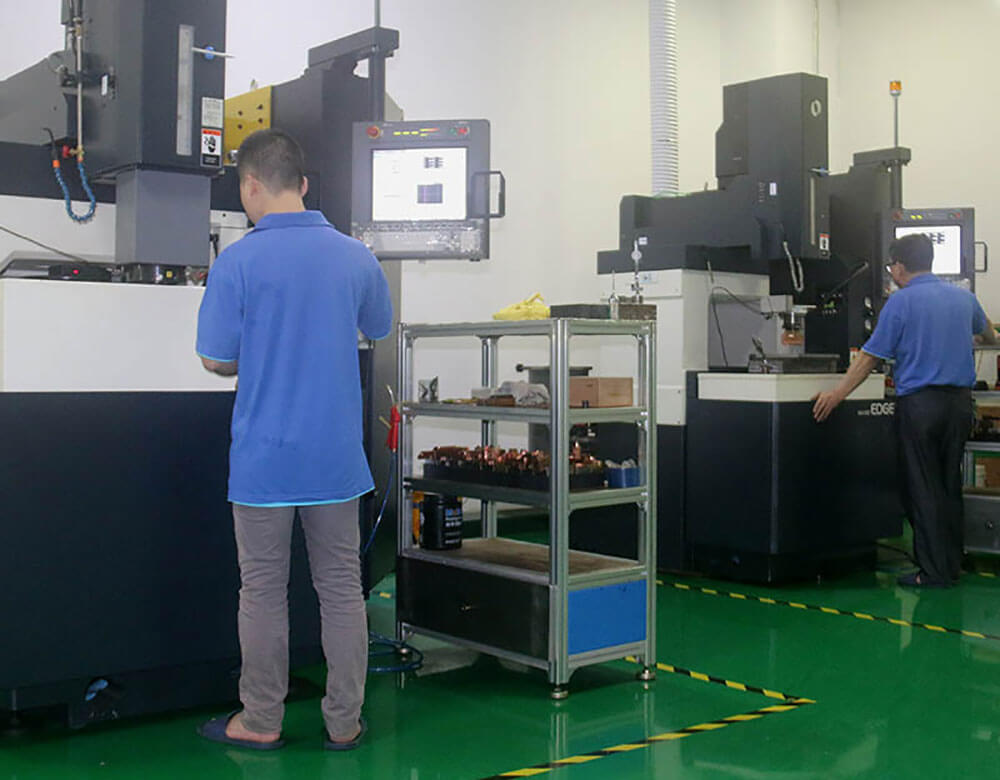

Factory Show

Advanced Micron-Level Tooling

Lingshantech cooperates with many-sided tooling manufactory technology, can achieve micron-level in tool manufacturing, and it perfectly achieved required precision for LSR tool. By using ARBURG、2KM etc. manufacturing equipment, we can make ultra-precision LSR products with weight minimum to 0.01g,thickness minimum to 0.05mm.

Equipment

Lingshantech has 60 ton - 360 ton LSR injection molding machines 12 sets,3000 square feet injection molding room including 250 square feet class8 clean room.We can produce parts from 0.01pound to 13 pounds.

Mold Making Shop

Lingshantech has In-house tooling - fully equipped 3000 square feet tool room,making sure your molds making in house,providing free mold routine maintenance,and also mold repair work if you need.