Post Molding Processing Service

Lingshan Tech offers customers a comprehensive and systematic approach to post- molding processing to meet their varying needs for product appearance and performance.

Value-Added Secondary Processes of Silicone,Plastic,Metal Parts

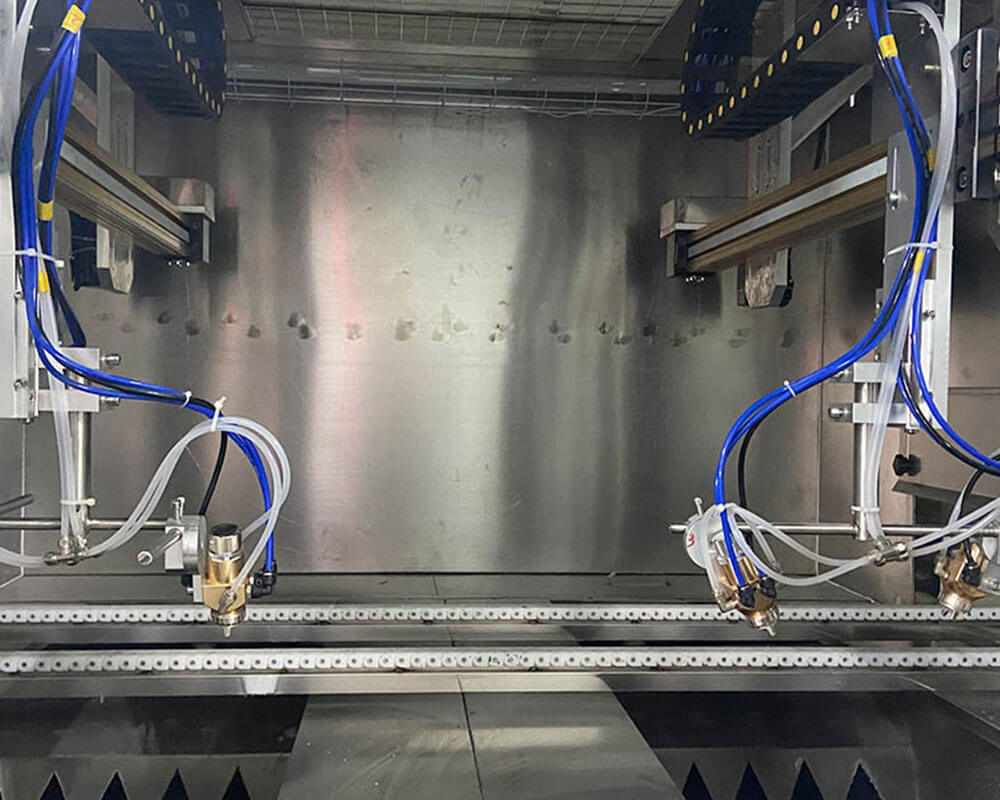

We prioritize post-molding processes for plastic and silicone parts, focusing on quality, functionality, and aesthetics. Our strategy includes automation, where our experienced team employs custom fixtures to ensure precise part alignment and consistency. We offer services like laser engraving, marking, printing, painting, and silicone oil coating. Our systematic approach adds value and efficiency to your projects, and we're actively exploring cost-effective automation solutions for post-molding operations.

Why Choose Us for Custom Post Molding Processing Service?

Custom Fixtures

Our custom-designed fixtures are precision-tailored to the specific requirements of each part. This eliminates variations in part positioning, reducing the chances of defects and ensuring consistent results for every unit.

Comprehensive Services

We offer a wide range of post-molding processing services, including laser engraving, laser marking, printing, painting of plastic parts, and silicone oil coating and spraying. We can meet various product appearance needs and optimize processes to add value to your projects.

Visual Impression

Our goal is to help you create injection-molded parts that are not only functional and durable but also visually impressive. We pay attention to the aesthetics of your products.

Part Joining and Assembly

We provide post-processing services such as part joining, increasing durability, painting, light assembly, and protective packaging to ensure your parts are ready for use upon delivery.

Our Unique Points

An extensive range of customizable options, seamless collaboration for tailored solutions, and swift manufacturing to capitalize on market opportunities and meet urgent demands

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Seamless Customization

We collaborate closely with you to bring your vision to life. With a wide array of materials, colors, and finishes, your creative ideas take shape with precision and unmatched quality.

Shorter Delivery Times

We can start manufacturing immediately according to your needs, achieving rapid delivery, enabling you to seize the market opportunities and meet urgent customer demands.

Start Custom Post Molding Service

Discover how our custom post-molding services can elevate your product's quality, functionality, and aesthetics.

Post-molding Processing for Silicone Parts

- Silicone Oil Coating

- Color Coating or Dyeing

- Laser Engraving

- Printing

- Surface Texture Treatment

- Assembly

- Silicone Curing

- Cleaning and Packaging

Post-molding Processing for Plastic Parts

- Decoration Methods

- Mold-Tech textures

- plastic spraying

- Pad printing

- Silk Screening

- Plating

- UV spray

- Laser engraving

Post-molding Processing for Metal Parts

- Surface Finishing

- Deburring

- Heat Treatment

- Coating and Plating

- Precision Machining

- Assembly

- Testing and Inspection

- Packaging and Shipping

- Value Add Assembly

- Contract Packaging

- Adhesive Bonding

- Spin Welding

- Ultrasonic Welding

- Thermo Sealing

- Heat Staking

- Thermoforming

What Is Post-molding Processing ?

Post-molding processing, also known as post-mold processing or post-processing, refers to a series of additional steps and treatments performed on a product or component after it has been molded or manufactured. This phase is essential to achieve specific quality, functionality, or appearance requirements that cannot be fully addressed during the molding process itself. Post-molding processing can be applied to various materials, including plastics, metals, ceramics, and composites, and it plays a crucial role in delivering finished products that meet or exceed design specifications.

The Advantages of Post-molding Processing Techniques Are as Follows:

- Precision Molding

- Improved Surface Quality

- Increased Strength and Durability

- Defect Removal

- Customization

- Material Savings

- Expanded Applications

Specialized Environment

Some parts require special environments during the manufacturing process.

Some of our specialized process environments we provide:

- Filling in Class 8 clean room

- Climate Controlled Environment

- Annealing: both air and oil

- Climate Controlled Packing

Applications of Post-molding Processing Techniques

Automotive Industry:

● Trimming and Deflashing

● Painting and Coating

● Assembly

Consumer Electronics:

● Surface Finish Enhancement

● Ultrasonic Welding

● Coating and Plating

Medical Devices:

● Quality Inspection

● Packaging

Aerospace Industry:

● Heat Treatment

● Assembly and Fastening

Consumer Goods:

● Surface Coating

● Customization

Packaging Industry:

● Trimming and Cutting

● Printing and Labeling

Construction and Building Materials:

● Surface Treatment

● Assembly

Industrial Equipment:

● Heat Resistance Treatment

● Assembly

Environmental and Sustainability:

● Recycling

● Waste Management