What We Do?

Lingshantech provides end-to-end support from concept to final product. Our services range from prototype design to assembly, serving many industries such as forestry, horticulture, telecommunications, furniture, hygiene, electrical appliances, packaging and so on. Our core competencies include precision machining, plastic and metal fabrication, and innovative assembly solutions.

Wide Material Selection

Our material repertoire spans plastics, silicone, and a variety of metals, empowering you to select the most suitable materials for your project to achieve the desired performance and characteristics.

Customized Solutions

Whether you require tailor-made components or standard industrial equipment parts, we provide tailored solutions to meet your specific requirements, ensuring the final product aligns with your unique needs.

Exquisite Technological Expertise

Equipped with advanced technological processes, we can accommodate intricate geometries, high precision machining, and multi-material combinations, guaranteeing optimal performance and quality for your products.

Quality Management

Enforcing stringent quality management systems, we ensure each manufacturing step adheres to industry standards and quality requirements, delivering consistent high-quality products.

Quality Essentials

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAI) Report

- PPAP Report (Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistical Process Control)

Instant Quotes & DFM Support

- Confirm a price in a very short time

- Manage countless iterations of customized parts

- Upload different designs to compare pricing options

- Receive instant DFM guidance

Fast Manufacturing

- Timely and precise, consistently

- Worldwide manufacturing choices

- Obtain components in single units or bulk quantities

Why Choose Lingshantech for Automotive Manufacturing?

Instant Quotation

We offer a streamlined experience for industrial equipment prototyping and custom manufacturing. Our instant quotation platform provides instant pricing and lead times, along with DFM analysis feedback. You can easily manage and track your orders through our platform.

High Precision Parts

Lingshantech specializes in custom manufacturing of industrial equipment parts that meet precise requirements. Our manufacturing capabilities enable us to produce industrial parts with tolerances as tight as +/-0.05mm.

One-stop Solution

Our wide array of cutting-edge processes and materials ensures we are well-equipped to handle a broad spectrum of industrial component requirements, catering to varied specifications and demands. From concept to completion, encompassing design, prototyping, and production, we provide a one-stop solution for your industrial component development.

Collaborative Partnership

We view our clients as valued partners, working closely with you to understand your needs, provide expert guidance, and deliver tailor-made solutions that align with your industrial objectives.

Optimizing Projects for Industrial Components

Tool & Mold Building

A successful part starts with a well-designed mold. This complex and precise process determines part manufacturability and lifecycle costs, and it takes into account the key components of mold design while adhering to a part's unique specifications. Proper mold design and mold building will help reduce cost, increase quality and optimize performance.

We use the latest CAD technology and software to create a robust mold design that's built to SPI standards, as well as moldflow analysis to evaluate all mold designs and parts prior to development.

Design for Manufacturability

This robust process employs strategic preparation and applies strict quality controls to ensure a consistent product output—and a competitive advantage for customers. DFM is the cornerstone for every project Lingshantech undertakes because the design and engineering process is critical to success.

Materials Selection

When developing a new part, determining the right material is essential. As part of the DFM process, understanding the requirements and performance characteristics of the part allows Lingshantech to determine the best material for your project.

Metrology

Our commitment to quality is based on stringent guidelines and blends seamlessly with our deep manufacturing knowledge and experience.

Materials for Consumer Electronics Parts

- Steel & Stainless Steel: 303, 316/316L, 15-5, Tool Steels, 4140, 1.7225

- Aluminum: 6061-T6, 6082, 7075-T6, 5083-H111, 2017

- Brass & Copper Alloys: C360, Copper C110, Copper C101

- Thermoplastics: Polyoxymethylene (POM), Polypropylene(PP),Polyethylene(PE),PolyvinylChloride( PVC),Polystyrene( PS),Polycarbonate(PC),Polyester(PET),Polymethyl Methacrylate(PMMA)

- Thermosetting Plastics:Epoxy Resin,Phenolic Resin,Polyketone Resin,Polyetheretherketone(PEEK),

- Silicone&LSR

- Nylon

Industrial Machinery Surface Finishes

- Anodizing:

- Powder coating

- Electroplating

- Bead blasting

- Passivation

- Heat treatment

Lingshantech’s Molding Technology for Industrial Components

Metal Stamping

Metal stamping is valued for its efficiency, precision, and large-scale production capabilities. In industry, it's key for crafting fasteners like nuts, bolts, washers, and pins. It's also pivotal for creating mechanical transmission components such as gears, chains, and racks. Furthermore, metal stamping is applied to produce heat sinks and radiators, regulating temperatures to ensure optimal equipment functionality.

Die Casting

Die casting is widely used in industrial parts manufacturing because of its high precision and efficiency. It is used to produce components such as enclosures, structural components, transmission components, radiators and more.

3D Printing

3D printing offers diverse applications in industrial component manufacturing, from rapid prototyping and customization to intricate geometry fabrication. It's suitable for small-batch production, enhancing performance through component integration. Materials range from plastics to metals, catering to various industrial demands.

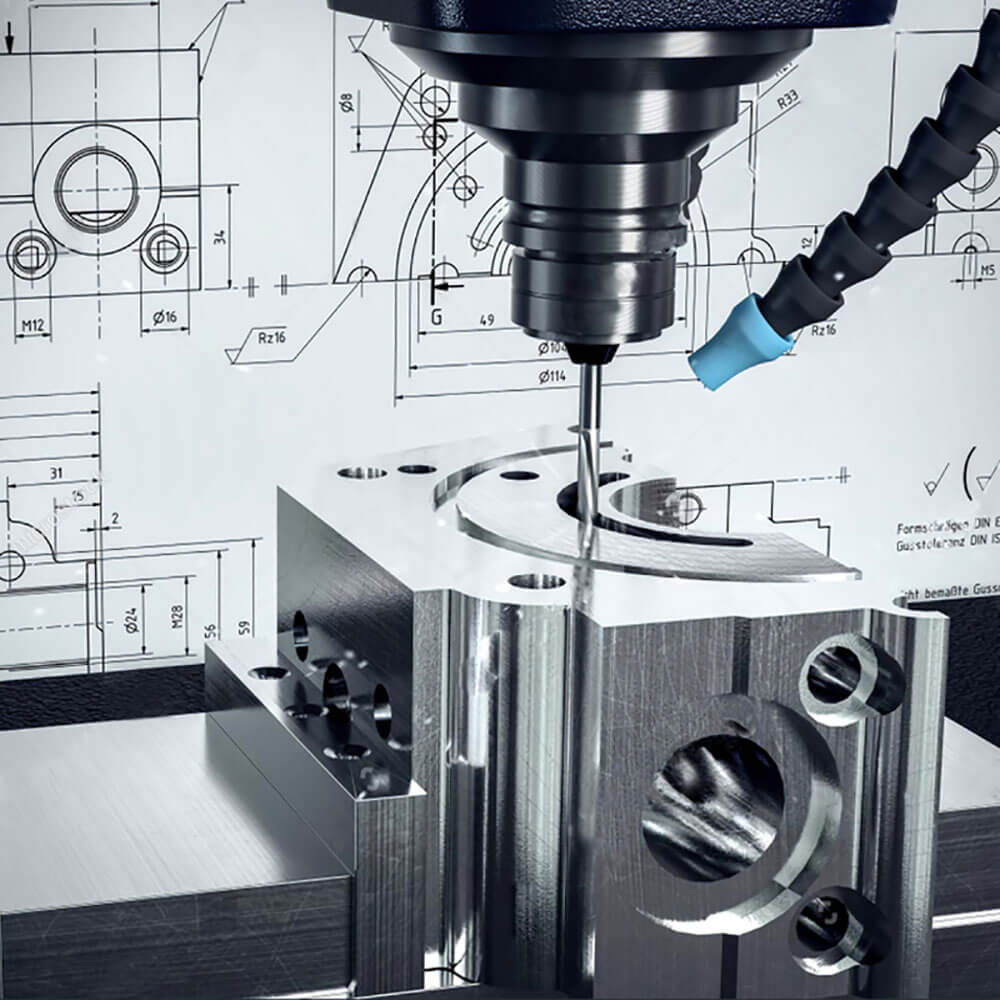

CNC Machining

For industrial components requiring high-precision machining, such as gears, shafts, and threads, CNC machining offers precise cutting and processing capabilities, ensuring the accuracy and performance of the components.

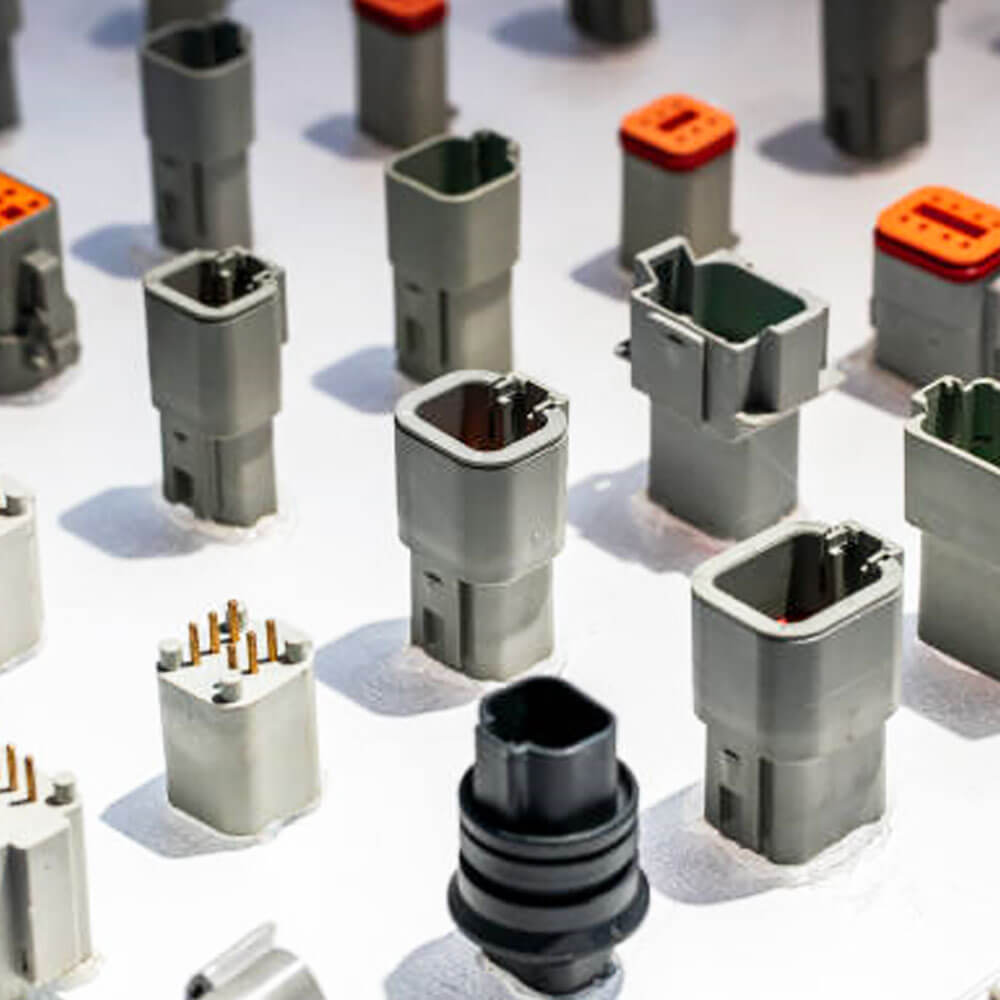

Plastic Injection Molding

Plastic injection molding is widely applied in industrial component manufacturing. It produces complex parts like housings, connectors, and brackets. It also crafts insulation components, seals, and pads, offering protection and isolation. Its controlled process suits precision-demanding applications, enabling efficient large-scale production, providing a reliable solution for industrial components.

Silicone Injection Molding

Silicone injection molding has diverse applications in industrial components. It's utilized to create seals, gaskets, O-rings, and intricate silicone parts. Additionally, silicone injection molding is employed for crafting protective covers, dampeners, and insulation components that enhance durability and performance. Its flexibility, chemical resistance, and suitability for complex shapes make silicone injection molding crucial for manufacturing reliable and versatile industrial solutions.

Custom Parts for Industrial Applications

ALingshantech excels in crafting top-quality manufacturing solutions for custom industrial components and standard equipment parts. With outstanding capabilities, we cater to diverse applications in the industrial sector. From custom-made components to standard parts, we're your partner in the custom component industry.

- Machine and tool parts

- Jigs and fixtures

- Electronic housings

- Pumps and accessories

- Oil and gas extraction equipment

- General industrial machinery

- Conveyors and conveying equipment

- Parts for tractors, bulldozers, forklifts, and other heavy construction and individual vehicles and equipment

More Industries

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries.