Assembly Solutions

Bringing Together Your Components. Our custom assembly services in silicone, plastic and metal material ensures quality, saves time, and meets unique project specifications.

Custom assembly for project-specific needs

Ensured precision & quality in every assembly

Seamless integration with our manufacturing

Comprehensive Assembly Solutions at Lingshantech

Lingshantech offers an array of assembly and joining technologies, including silicone and plastic injection molding, adhesive bonding, plastic ultrasonic and vibration welding, heat staking, gluing, metal threaded connection and welding, also including assembly parts packing of color box and heat shrinking.

Why Choose Us for Assembly Service?

Assembly of Components

With our extensive knowledge and experience in silicone, plastic, and metal assembly, we are committed to consistently providing highly efficient solutions.

Capabilities

Our extensive capabilities encompass all aspects related to the materials of rubber, polymer and metal, ranging from production to post-processing and beyond.

Endless Assembly Options

Select from a wide array of material combinations, finishes, tolerances, markings, and certifications available for your custom assembly order.

Quality Assurance

Lingshantech’s assembly service is a great choice for high quality , ISO9001:2015, IATF16949 certificated products in delivering competitive solutions that are timely, accurate, and of high quality.

Our Unique Points

An extensive range of customizable options, seamless collaboration for tailored solutions, and swift manufacturing to capitalize on market opportunities and meet urgent demands

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Seamless Customization

We collaborate closely with you to bring your vision to life. With a wide array of materials, colors, and finishes, your creative ideas take shape with precision and unmatched quality.

Shorter Delivery Times

We can start manufacturing immediately according to your needs, achieving rapid delivery, enabling you to seize the market opportunities and meet urgent customer demands.

Getting Manufacturing & Assembly Services

Experience Unparalleled Precision and Efficiency with Our Tailored Component Manufacturing&Assembly Services.

Lingshan Tech’s Multi-material Assembly Solutions

Versatility in Materials: is one of the key highlights of Lingshan Tech's component assembly solutions. We excel in assembling various materials, including plastic, silicone, metals, and more. This versatility allows us to meet different product requirements and applications.

Plastic Assembly: Plastic is a widely used material in many industries due to its versatility, lightweight, and cost-effectiveness. At Lingshan Tech, we have extensive experience in assembling plastic components, ranging from simple designs to complex shapes. Our precision CNC machining capabilities ensure seamless fitting and precise alignment for the perfect integration of plastic parts.

Silicone Assembly: Silicone is valued for its unique properties, such as flexibility, heat resistance, and biocompatibility. We excel in assembling silicone components for applications in medical devices, consumer electronics, and automotive parts. Our expertise in handling silicone materials guarantees the seamless assembly of intricate silicone parts.

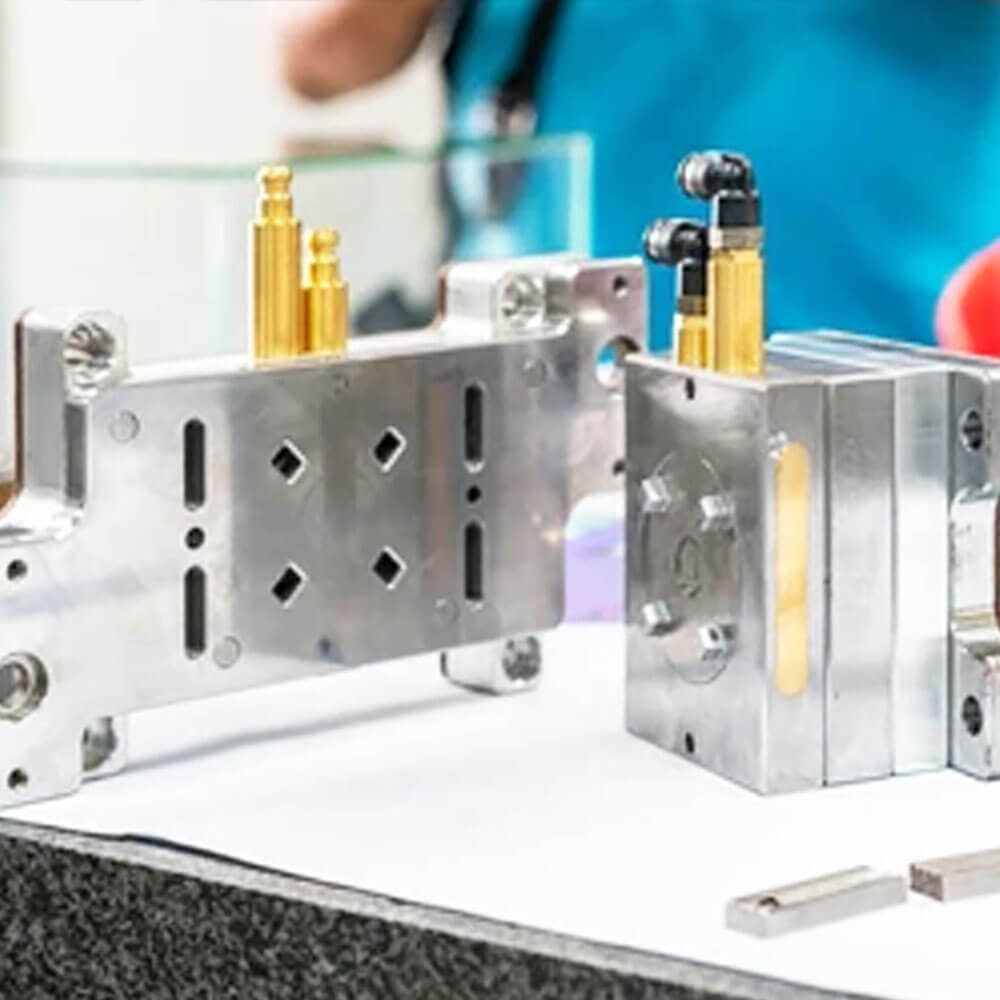

Metal Assembly: Metal components are prevalent in industries like aerospace, automotive, and machinery. With our advanced CNC machining and sheet metal stamping capabilities, we can efficiently assemble metal parts with high precision and accuracy. Whether it's steel, aluminum, or other alloys, our assembly process ensures optimal performance

Composite Materials: In certain industries, composite materials are preferred for their specific characteristics, such as high strength-to-weight ratio and corrosion resistance. We have the expertise to assemble components made from composite materials, ensuring their integrity and performance.

Combination of Materials: Many products require the integration of different materials to achieve optimal functionality. Lingshantech's versatility in material assembly enables us to handle complex projects that involve combining plastic, silicone, metal, and other materials seamlessly.

Adaptable to Diverse Industries: Our ability to work with various materials makes us well-equipped to serve a wide range of industries, including automotive, electronics, healthcare, aerospace, and consumer goods. From prototyping to mass production, our assembly solutions can accommodate different industries' specific needs.

Design for Assembly (DFA)

Design for Assembly(DFA) is an engineering approach and methodology that emphasizes designing products with ease of assembly in mind. The main objective of DFA is to simplify the assembly process, reduce manufacturing costs, and improve product quality and efficiency. It involves considering the ease of handling, positioning, and fastening of components during the assembly process.

Our Design for Assembly (DFA) method offers numerous advantages to our clients. By applying DFA principles during the product design phase, we streamline the assembly process, lower production costs, and enhance product quality and reliability.

Moreover, our DFA approach aligns with the principles of sustainability by promoting efficient resource utilization, resulting in more environmentally friendly and sustainable products.In summary, our DFA method provides clients with superior, efficient, and reliable product solutions.

Design for Disassembly (DFD)

We actively promote the concept of "Design for Disassembly (DFD)," deeply integrating it into our component assembly solutions. During the product design phase, we fully consider the disassembly and recyclability of components, employing modular design and reversible connectors to ensure components can be disassembled without damage and conveniently reused. Furthermore, we introduce identification and recognition technologies to enhance recycling efficiency and resource reuse. Through these measures, we significantly reduce the adverse environmental impact of discarded products, aiming for sustainable development and providing customers with more environmentally friendly and sustainable component assembly solutions.

The Advantages of Post-molding Processing Techniques Are as Follows:

Part Pre-treatment

Part Positioning and Alignment

Connection Techniques

Adjustment and Debugging

Inspection and Verification

Packaging

Traceability

Quality Control

Interference fit

Snap-fit assembly

Mechanical joining

Welding assembly

Adhesive bonding

Solvent bonding

Custom Requirements

Engineering Support

Efficiency and Automation