Custom CNC Milling Services

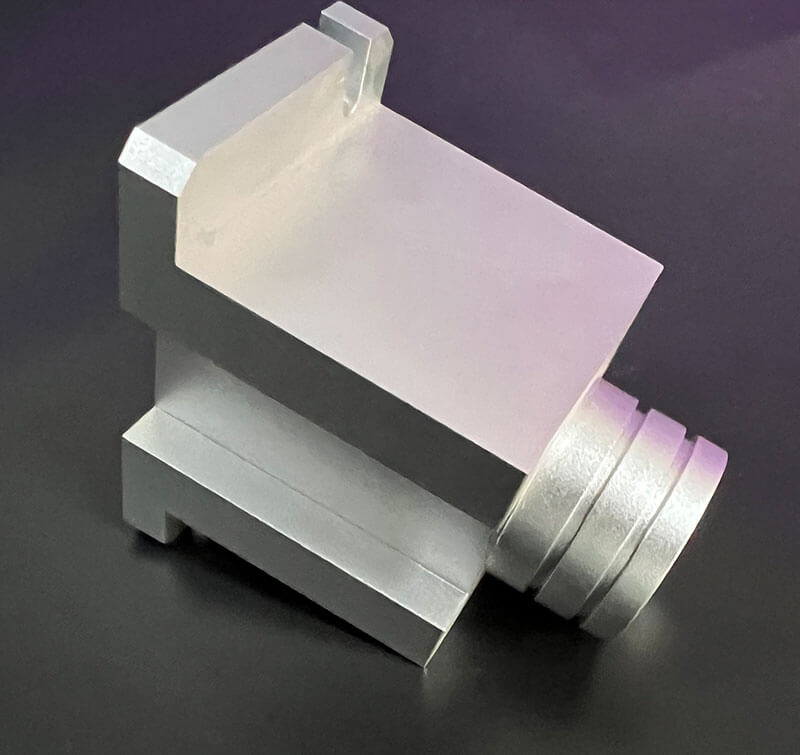

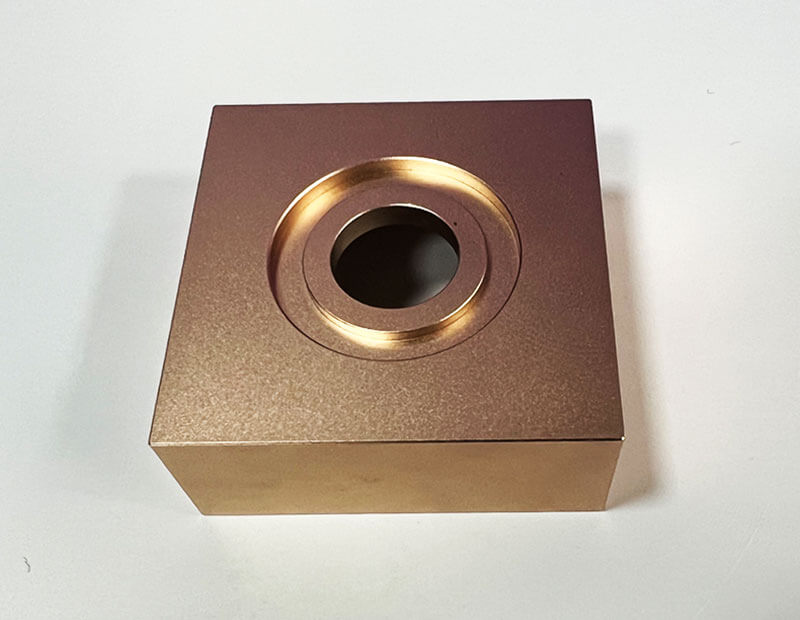

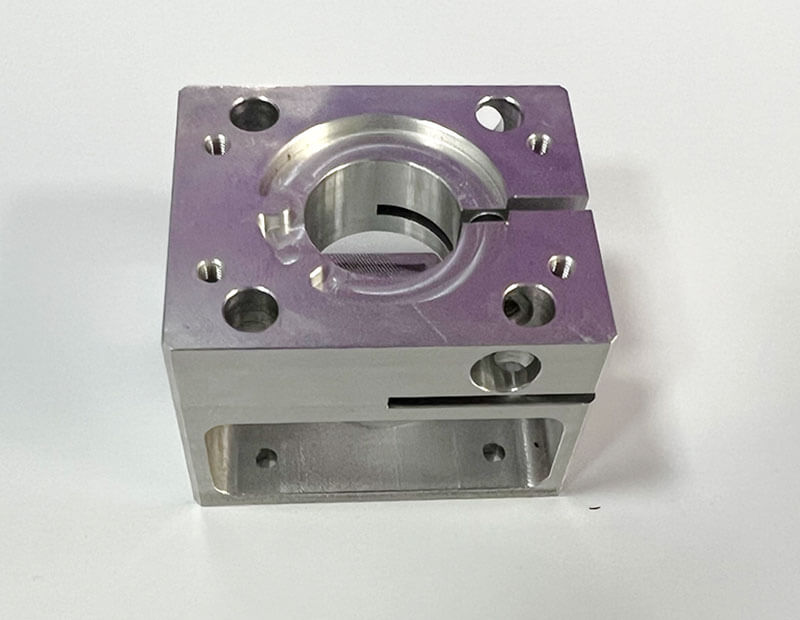

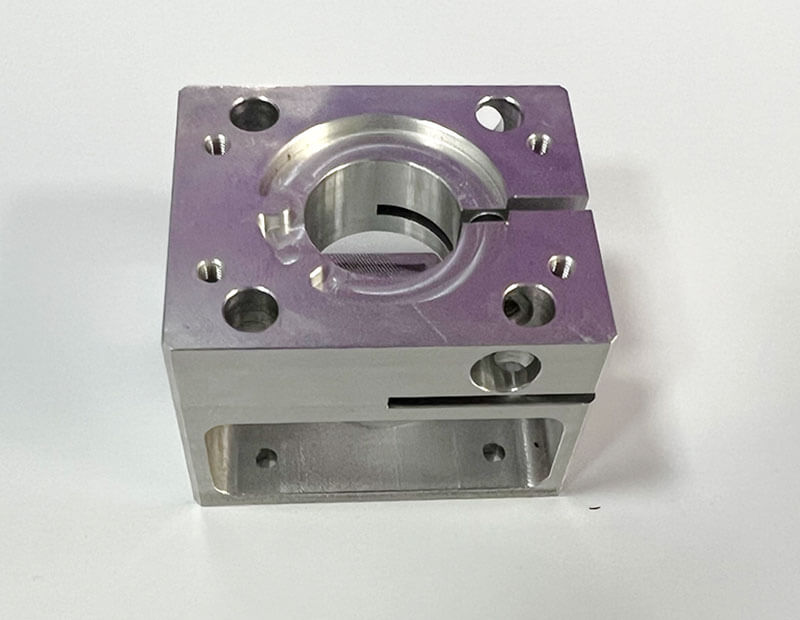

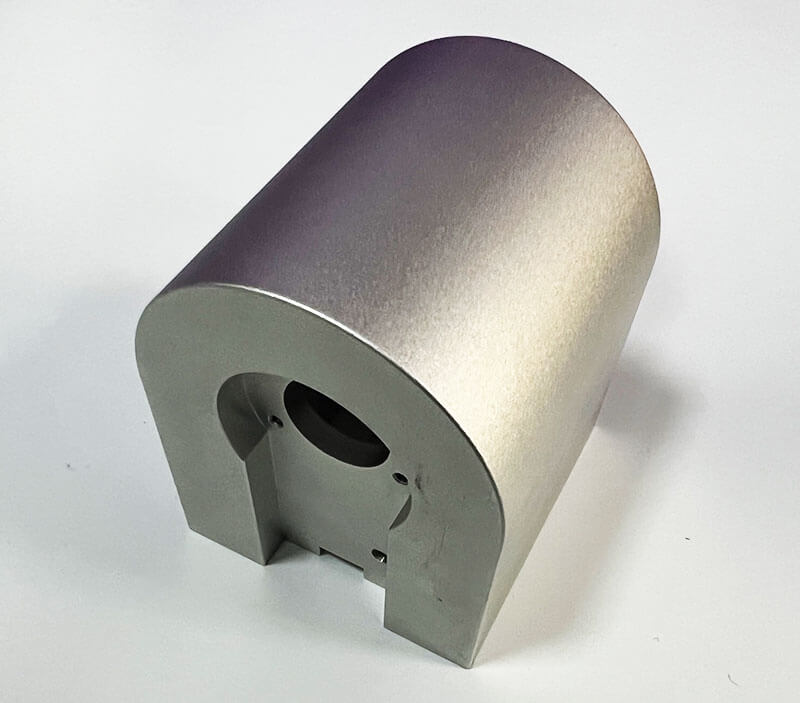

CNC milling services available on-demand for both rapid prototypes and production components. Obtain superior custom-milled parts crafted from a wide range of high-quality metals and plastics, all at competitive prices.

3, 4, 5 Axis Milling

ISO 9001:2015

IATF16949

Reliable CNC Milling Services

At Lingshantech, we have full capacity workshops and machines capable of CNC milling, supporting 3-axis, 4-axis, 5-axis, and right angle milling capabilities. Whether you need simple straight lines or intricate geometric shapes, we offer instant pricing, on-demand lead times, and design-for-manufacturability(DFM) feedback for your custom CNC milled parts.

We offers fast prototyping and efficient production with diverse surface treatments, ensuring timely delivery of high-quality CNC milled parts. Adhering to ISO 9001 standards, our experienced team provides personalized support for design, materials, and project needs. Trust us as your reliable partner for tailor-made CNC milling solutions and enhanced product quality.

Why Choose Us for Custom CNC Milling Service?

Our advanced CNC machining solutions, combining high-performance machines, precision tools, advanced controls, CAD/CAM expertise, rigorous inspections, and a skilled technical team to meet your specific needs.

Advanced CNC Milling Machines

We utilize high-performance CNC milling machines with multi-axis linkage capability, enabling simultaneous cutting in multiple directions and achieving high-precision machining for complex parts.

Advanced Control System

Leveraging advanced CNC technology, we achieve precise control over tool positions and movements, enabling the machining of complex shapes and intricate details.

Inspection Equipment

Equipped with advanced inspection devices, including coordinate measuring machines and spectrometers, we conduct comprehensive quality inspections to ensure each workpiece meets strict quality standards.

High-Precision Cutting Tools

Equipped with high-precision cutting tools, we achieve micro-level precision machining, ensuring each workpiece meets stringent dimensional and surface quality standards.

CAD/CAM Software

Our team uses advanced CAD/CAM software for design and programming, swiftly generating machining paths to enhance production efficiency.

Professional Technical Team

With our experienced technical team proficient in CNC machining, we offer customized solutions tailored to specific customer requirements.

Our Unique Points

An extensive range of customizable options, seamless collaboration for tailored solutions, and swift manufacturing to capitalize on market opportunities and meet urgent demands

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Seamless Customization

We collaborate closely with you to bring your vision to life. With a wide array of materials, colors, and finishes, your creative ideas take shape with precision and unmatched quality.

Shorter Delivery Times

We can start manufacturing immediately according to your needs, achieving rapid delivery, enabling you to seize the market opportunities and meet urgent customer demands.

Start Making Custom CNC Milling Service

Get custom milled parts for rapid prototyping and production.Send us your inquiries today for top-quality results and quick turnaround times.

Available 3D Printing Materials

Note:The 3D printing technology is constantly evolving, and new materials may emerge in the future, so this list may not be exhaustive. When choosing materials, factors such as printer compatibility, required performance, application areas, and cost need to be taken into consideration.

Metals

Aluminum

Brass

Copper

Stainless Steel

Steel Alloy

Steel Mild Low Carbon

Titanium

Plastics

ABS

Acetal

CPVC

HDPE

LDPE

Nylon

PEEK

PEI

PET

PMMA

Polycarbonate

Polypropylene

POM (Delrin)

PPSU

PS

PSU

PTFE

PVC

Note: The 3D printing technology is constantly evolving, and new materials may emerge in the future, so this list may not be exhaustive. When choosing materials, factors such as printer compatibility, required performance, application areas, and cost need to be taken into consideration.

CNC Milling Tolerances & Standards

| Description | General Tolerance or Standard |

| Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

| Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

| Orientation and Form Dimensions | 0-12" +/- 0.005", Angularity 1/2 degree. For 24" and beyond please consult Xometry's Manufacturing Standards. |

| Precision Tolerances | Can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts. |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | Can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

| Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

Surface Finish Options for CNC Milling

- Available Finishes

- Polishing

- Grinding

- Sandblasting

- Etching

- Electrical Discharge Machining (EDM)

- Coating

- Anodizing

- Painting

What Is CNC Milling and How It Works?

CNC milling, or Computer Numerical Control milling, is a precision machining process used to remove material from a workpiece to create custom-designed parts, components, or prototypes. It involves the use of computer-controlled machines known as CNC milling machines or mills, which are equipped with rotating cutting tools.

Digital Design

The process begins with creating a 3D digital model of the object you want to print. This model can be generated using computer-aided design (CAD) software or obtained from 3D scanning technologies.

Toolpath Generation

Once the digital design is complete, specialized software is used to generate the toolpaths. Toolpaths are the precise instructions that guide the CNC milling machine on how to move and position the cutting tool during machining.

Material Fixturing

The workpiece (the material from which the part will be milled) is securely fixed or clamped onto the milling machine's worktable.

Machining

The CNC milling machine follows the generated toolpaths to remove material from the workpiece. The cutting tool rotates at high speeds and can move in multiple axes (commonly X, Y, and Z axes) with precision control.

Completion

Once the machining process is complete, the finished part is removed from the milling machine, and any additional finishing processes, such as surface treatments or assembly, may be applied.

CNC Milling Machine Setup

The CNC milling machine is set up with the appropriate cutting tool (such as an end mill, ball mill, or drill) and the necessary toolholders.

Quality Control

During and after machining, quality checks and measurements are performed to ensure the part meets design specifications and tolerances.

CNC Milling Offers Several Advantages

Precision

Versatility

Efficiency

Complex Geometries

Applications

Aerospace

Automotive

Medical Devices

Electronics

Tool and Die Making

Prototyping

Industrial machinery

Agriculture

Renewable Energy

Dental

Art and Sculpture