Custom Plastic Injection Molding Service

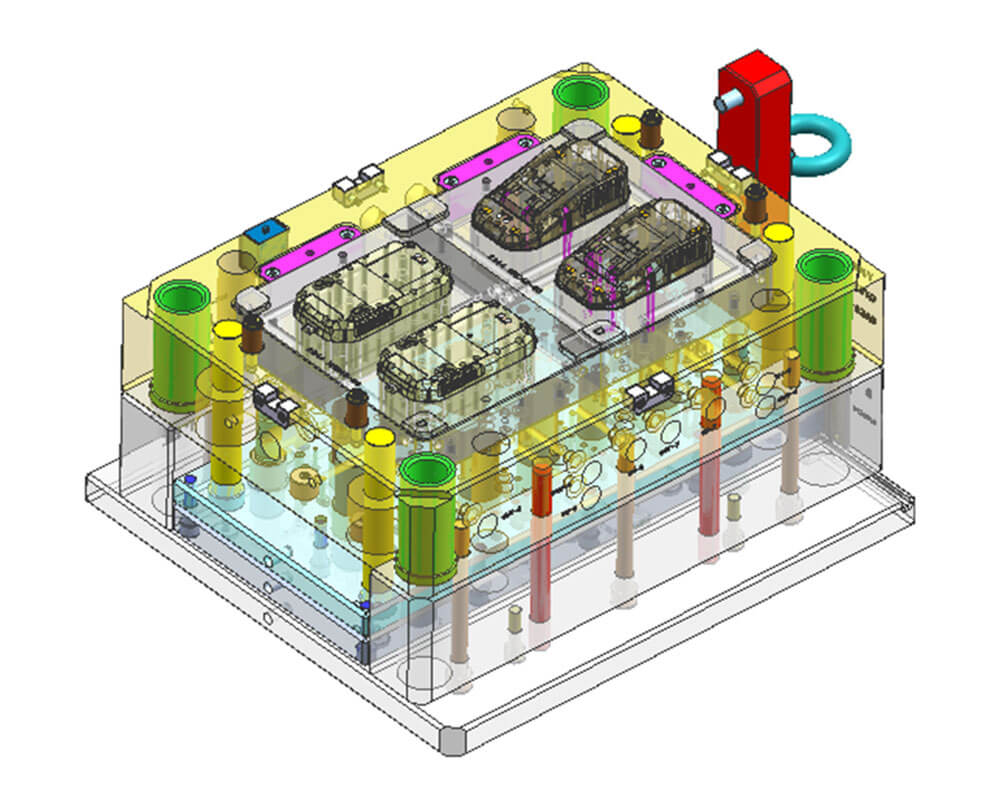

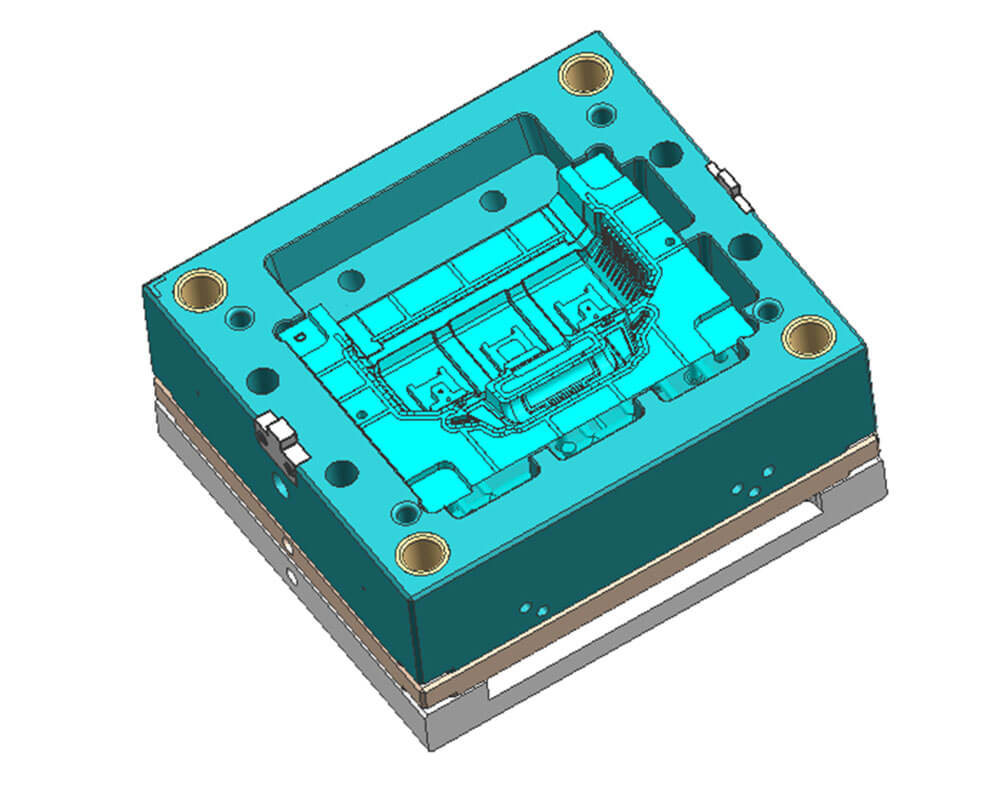

From complex components to simple products, we rely on skilled mold designers, advanced software technology, and high-end CNC machinery to produce high-quality molded plastic parts.

Get custom plastic molded prototypes and production parts within days.

Dozens of materials and finishes are available.

ISO9001:2015

IATF16949

Our Comprehensive Plastic Injection Molding Service

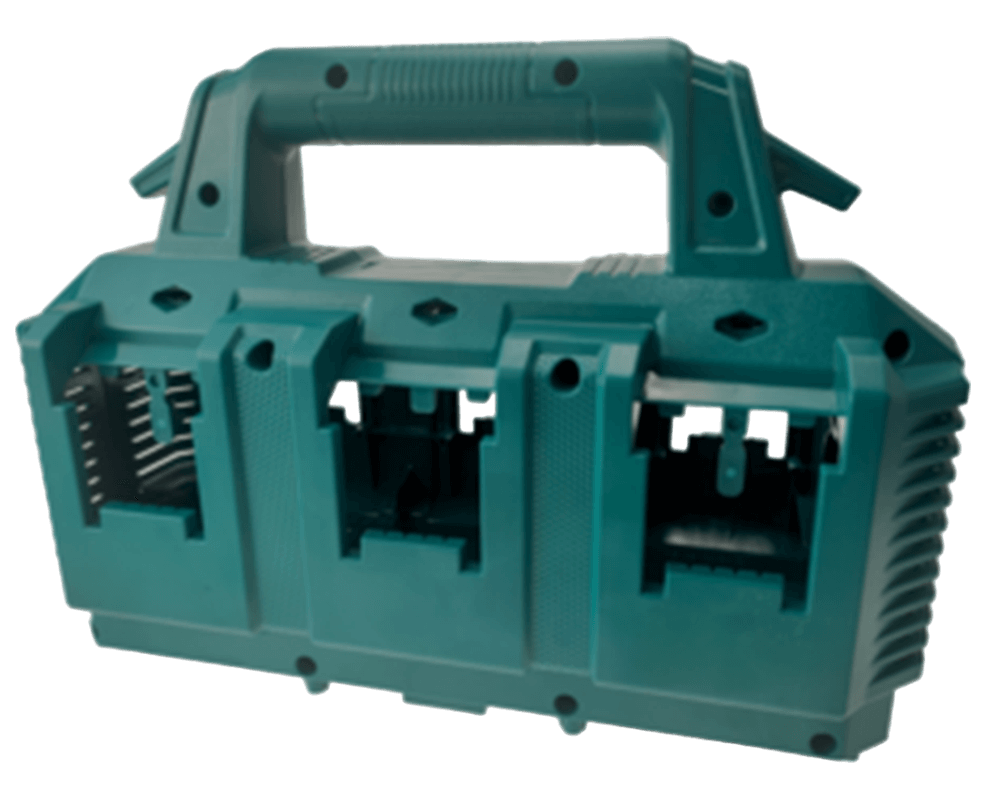

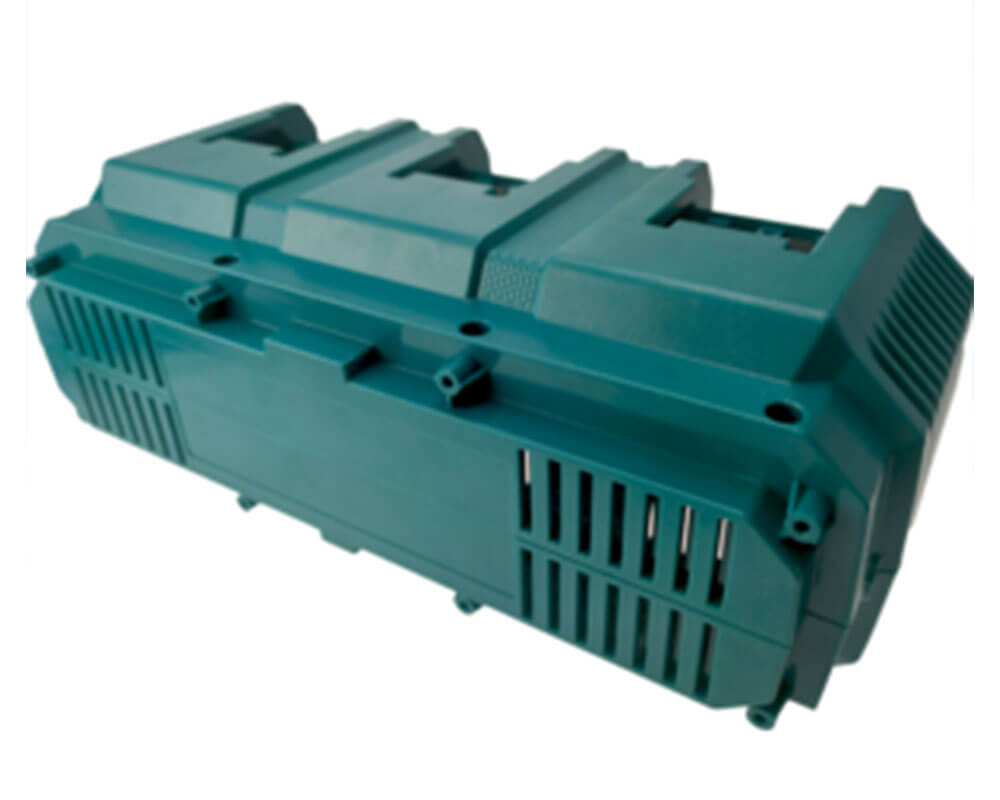

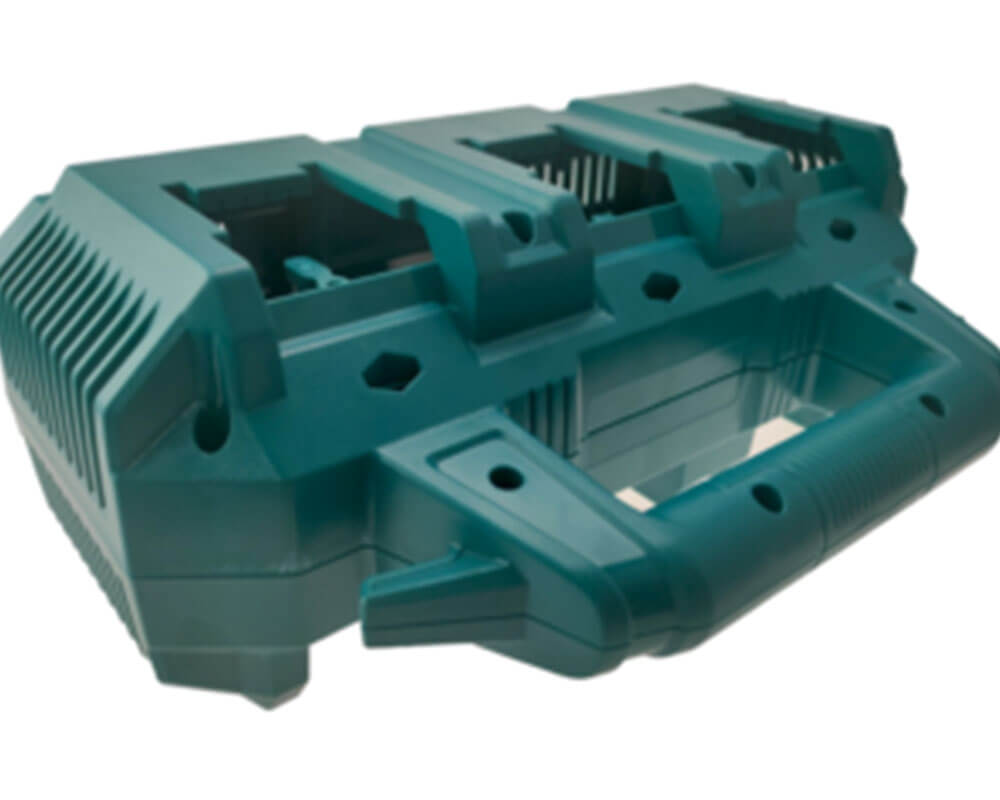

We manufacture plastic parts ranging in size from 3 millimeters to 1 meter, regardless of complexity, and offer industry-leading shortest delivery times, with the fastest being just 20 days. Our manufacturing equipment encompasses injection machines ranging from 60 to 1300 tons, suitable for various part sizes, complexities, and production volume requirements. For precision needs, we can provide tighter tolerances upon request. Partner with us for on-time delivery of high-quality, tailor-made parts to meet your specific requirements.

Lingshantech is a specialized plastic injection molding company, providing complete manufacturing solutions for your projects. Our custom plastic injection molding services encompass on-demand prototyping and production. We excel in delivering high-quality plastic injection molded parts, regardless of their size or complexity

Why Choose Lingshantech for Plastic Injection Molding Parts?

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

High Precision &Complex Geometries

Through precise mold design and advanced injection molding techniques, we can produce plastic parts with high precision and intricate geometries. Whether you require fine details or complex structures, we can meet your requirements.

Mass Production&High Efficiency

Plastic injection molding allows for the simultaneous production of multiple identical or different parts, increasing production efficiency. Our advanced equipment and automated processes reduce production cycles and minimize manual intervention, resulting in cost-effective manufacturing.

Material Diversity & Customization

We offer a wide range of plastic materials to meet the requirements of various industries and applications. Depending on your project needs, we can select suitable materials and accommodate color adjustments, surface treatments, and special requirements.

Our Unique Points

An extensive range of customizable options, seamless collaboration for tailored solutions, and swift manufacturing to capitalize on market opportunities and meet urgent demands

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Seamless Customization

We collaborate closely with you to bring your vision to life. With a wide array of materials, colors, and finishes, your creative ideas take shape with precision and unmatched quality.

Shorter Delivery Times

We can start manufacturing immediately according to your needs, achieving rapid delivery, enabling you to seize the market opportunities and meet urgent customer demands.

Start Plastic Injection Molding Project Today

Access top-notch plastic injection molding services for your custom prototypes and production parts. Get injection molded parts with impeccable quality, excellent finishes, and high dimensional stability at competitive prices.

Available Materials for Plastic Injection Molding Parts

| Property | Materials |

| Impact resistant | ABS, PMMA, PVC, PE, PC |

| Wear-resistant | POM, PEEK, UHMW |

| Dimensional stability | ABS, PBT, HIPS, PPS |

| Chemical resistance | PEEK, PP, PBT, PE, LDPE, PA |

| Rubber like | TPU, TPE, Silicone |

| Cost-efficient | PP, HDPE, LDPE |

| Cosmetic | ABS, PC, HIPS |

| Part Size | Tolerance Range (mm) |

| Small-sized (<50 mm) | 0.05 - 0.2 |

| Medium-sized (50-200 mm) | 0.1 - 0.5 |

| Large-sized (>200 mm) | 0.5 - 1 |

Please keep in mind that these tolerance values are approximate and can vary depending on project specifics, material properties, and manufacturing capabilities. Customized tolerances can be determined through collaboration with the client to meet specific design and functional requirements for each project.

Surface Finish Options for Plastic Injection Molding

| FINISH | DESCRIPTION |

| PM-F0 | non-cosmetic, finish to Protolabs' discretion |

| PM-F1 | low-cosmetic, most toolmarks removed |

| PM-F2 | non-cosmetic, EDM permissible |

| SPI-C1 | 600 grit stone, 10-12 Ra |

| PM-T1 | SPI-C1 + light bead blast |

| PM-T2 | SPI-C1 + medium bead blast |

| SPI-B1 | 600 grit paper, 2-3 Ra |

| SPI-A2 | grade #2 diamond buff, 1-2 Ra |

What Is Plastic Injection Molding?

Plastic injection molding is a versatile manufacturing process that utilizes high-pressure injection of molten plastic into a mold cavity to produce a wide range of complex and durable plastic products. This is an ideal process for producing large volumes of standardized parts with excellent mechanical properties..

What Is Plastic Injection Molding:

- Complex Geometries

- High Precision

- Mass Production

- Material Diversity

- High Efficiency

- Low Waste

- Integrated Manufacturing

- Reliability

Applications of Plastic Injection Molding

Plastic injection molding technology finds extensive applications across various industries, including but not limited to:

Common 3D Printing Applications

- Automotive Industry: Manufacturing automotive components such as interior parts, exterior components, and functional elements.

- Electronics and Electrical: Production of plastic enclosures, connectors, wire harnesses, and other electronic components.

- Medical Devices: Manufacturing medical equipment and instruments like syringes, surgical tools, and implants.

- Consumer Goods: Production of plastic containers, household items, toys, and more.

- Industrial Components: Manufacturing plastic parts for machinery, aerospace, energy, and other industrial sectors.