Start your injection molding quote now

Service Hotline: +86 13625012311

Email address: judsonkang@lingshantech.com

Our research and development team consists of experienced engineers and designers. Our R&D achievements span across multiple industries, including industrial products, electronics, automotive components, medical devices, and more. We excel in the development of products using silicone, plastic, liquid silicone rubber (LSR), and metal materials, showcasing profound expertise and experience. Our R&D process encompasses market research, creative ideation, feasibility analysis, prototype production, testing, and continuous improvement. Our goal is not only to meet customer needs but also to lead the industry forefront.

Our team specializes in the R&D of ultra-precision products using silicone, plastic, LSR, and metal materials. Whether it's product dimensions, surface smoothness, or complex geometries, we meet the highest customer requirements. Product dimensional tolerances can be accurate up to 0.01 millimeters, ensuring product precision.

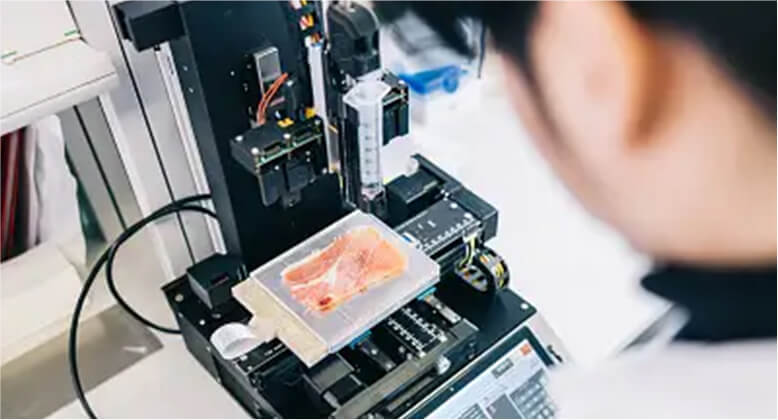

We possess advanced 3D printing technology and rapid prototyping equipment, allowing us to swiftly create product prototypes. This innovative approach enables us to validate designs and concepts early in the process,reducing product development cycles and costs.

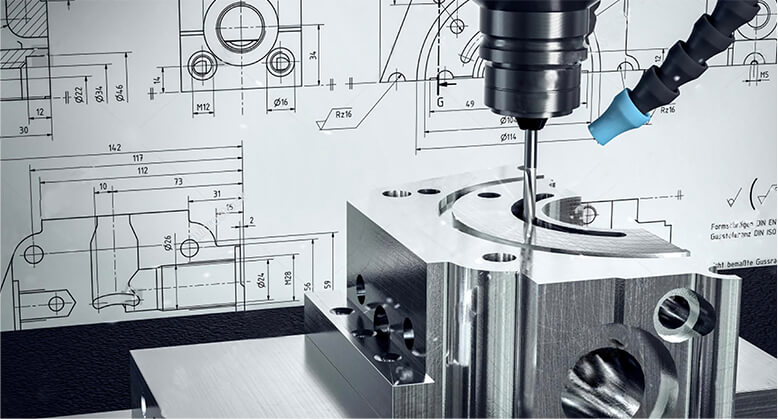

We emphasize innovation in mold manufacturing technology. With state-of-the-art mold processing equipment such as Roders, Makino, and Erowa, our mold dimensional tolerances are controlled within 0.005 millimeters, and mold lifespans extend up to one million cycles. This innovation guarantees product consistency and precision, laying a solid foundation for high-quality manufacturing.

In the field of metal CNC machining, we employ world-class machinery and multi-axis machining technology to achieve micron-level tool manufacturing. This innovation ensures high accuracy and reliability of metal components.

Lingshantech holds ISO 9001:2015 and IATF 16949 certifications, ensuring adherence to stringent quality standards. Our comprehensive reports, including First Article Inspection (FAI), PPAP, Material Technical Data Sheets (TDS), CMM Inspection, and SPC, underscore our commitment to quality.

We have made significant progress in the research and application of cold runner systems. This includes innovations in nozzle and valve opening, heating, and insulation techniques, aimed at enhancing production efficiency and product quality.

We strictly adhere to Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) specifications to ensure the controllability and stability of new products. Whether it's silicone, plastic, LSR, or metal materials, we maintain high quality and standards in new product development..

We collaborate with world-renowned material suppliers such as Wacker, Momentive, Shin-Etsu, Dowcorning, to jointly develop various high-performance materials catering to different product needs. Our research and application extend not only to silicone, plastic, LSR, and metal materials but also to new materials.

During pilot and mass production, we leverage expertise, advanced facilities, and quality control measures to efficiently produce high-quality products. Then a final and full inspection ensures the high quality.

Lingshantech collaborate to manufacture essential components crucial for optimal functionality. Our specialization lies in custom rubber formulations, silicone (including LSR), thermoplastics and metal, along with expertise in assembling components designed for high performance and dependability.

we is a leader in crafting high-quality prototypes for diverse applications. Using medical-grade, consumer electronics, and specialized materials, our skilled technicians analyze design files and create 3D-printed prototypes that closely resemble final products. Our Design for Manufacturing (DFM) analysis ensures designs meet testing standards, empowering precise evaluation of specifications and functional testing. Our commitment to efficiency guarantees a swift turnaround, enabling confident progress across industries.

Effortlessly modify and refine functional prototypes, tailoring them based on rigorous testing and performance validation. These prototypes meticulously replicate the final products, making it swift to detect and address design issues to meet performance standards. Through comprehensive analysis and optimization, we guarantee top-notch quality and reliability from the start. Our functional prototypes serve as visual representations, facilitating issue identification—an undeniable edge in the custom component industry.

Lingshantech streamlines the validation process with T0 samples for your medical, consumer electronics, and kitchen/bathroom products. These samples efficiently validate performance, functionality, and aesthetics, allowing essential design iterations to save time and costs. We provide manufacturing feedback, utilizing various materials, finishes, and mechanical designs to assess prototypes' performance and appearance. This ensures optimal functionality and market-ready finishes, aligning with your distinct requirements. Expert insights from our technical team enable refined designs, ready for smooth production—an advantage in custom components across industries.

We meticulously craft P0 samples using advanced machining techniques and a state-of-the-art quality management framework, tailored for efficient large-scale manufacturing in the kitchen, bathroom, and consumer electronics sectors. These samples incorporate your input, allowing us to evaluate manufacturability and suitability, leading to optimized production efficiency. Our technical expertise provides invaluable insights for design refinement, ensuring the final product meets the highest standards of quality and efficiency.

Anodizing is applied in varies industries to enhance the durability and aesthetic quality of components by improving corrosion and wear resistance. This process effectively elevates both the appearance and lifespan of the devices

Powder coating is an excellent option for medical devices due to its inherent antimicrobial properties, which foster a sanitary and sterile environment essential in the medical field.

Electroplating offers both aesthetic and functional advantages, enhancing the appearance and corrosion resistance of medical products. Moreover, this process enhances their mechanical properties, imparting greater durability to the devices.

Bead blasting is a surface treatment that enhances the aesthetic appeal while also extending their lifespan by reducing wear and tear on the components. This process effectively improves both the appearance and durability of the devices.

Passivation plays a crucial role by effectively eliminating particles from medical components, thereby preventing potential corrosion. This process significantly enhances the corrosion resistance of the products, ensuring their long-term durability and reliability.

Heat treatment is a valuable process, as it leads to notable improvements in their corrosion resistance, strength, and biocompatibility. This treatment significantly enhances the overall performance and reliability of the medical devices, making them more suitable for various applications in the healthcare industry.

We prioritize the exclusive procurement of materials from trusted suppliers who maintain certified quality management systems at their state-of-the-art facilities. Our suppliers boast a wide range of comprehensive certifications, including rohs, Reach, MSDS, FDA, LFGB, UL, EN549, BPA free, EN71, and more. By adhering to this rigorous sourcing approach, we guarantee full compliance with your industry's stringent requirements.

Our ISO Class 8 clean room injection molding is used to manufacture medical devices, medical devices, pharmaceutical packaging, biotechnology products and other products that require a high degree of hygiene and accuracy. By producing in a controlled environment, contamination and variation in the production process can be minimized, thereby improving the quality and reliability of the product.

In the manufacture of medical supplies, IQ/OQ/PQ Validation stands as a pivotal quality assurance and compliance procedure. This comprehensive process ensures that production equipment and processes function within controlled and dependable parameters, guaranteeing the manageability and uniformity of the production cycle.

We provide comprehensive quality documentation, including ISO 9001:2015 certification, IATF 16949 certification, First Article Inspection (FAI), Production Part Approval Process (PPAP) reports, Material Technical Data Sheets (TDS), Coordinate Measuring Machine (CMM) inspection reports, Statistical Process Control (SPC) reports, Material Certificates, Dimensional Inspection Reports (CMM), Design for Manufacturing (DFM) feedback, and more. The management of these documents ensures the traceability and control of product quality.

Throughout the research and development process, we employ cutting-edge inspection equipment and techniques, such as the Hexagon 3D Coordinate Measuring Machine, tensile strength testing apparatus, as well as various precision optical and projector inspection devices. These tools ensure the high quality and precision of our products during the production process and prior to delivery to our customers.

Take advantage of our network and see what LINGSHAN can do for you